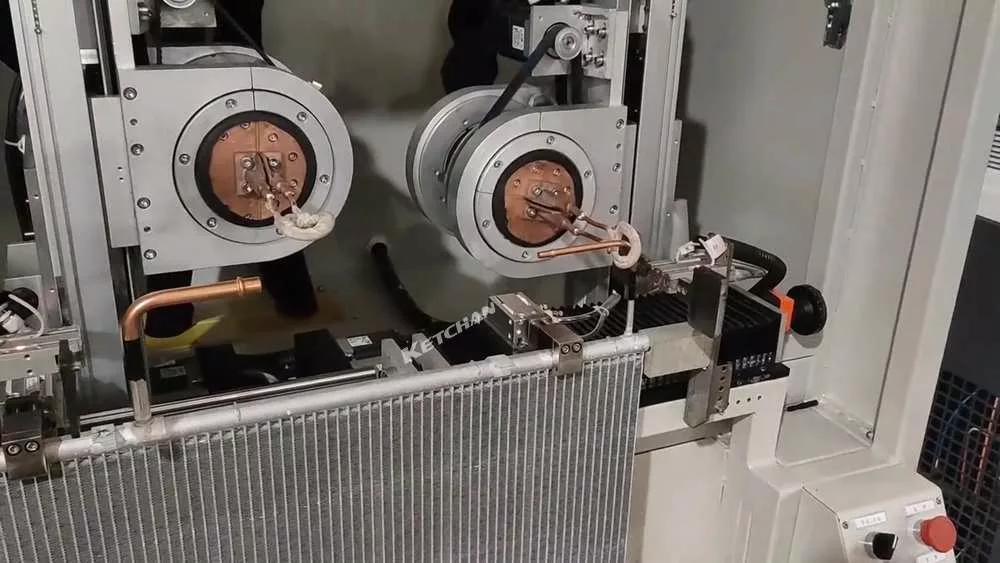

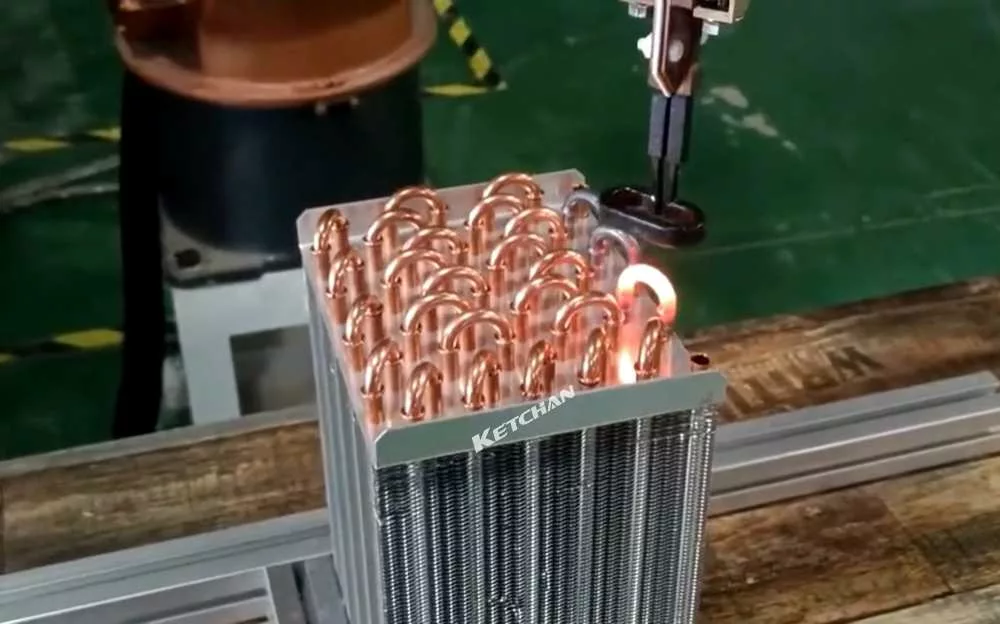

KETCHAN’s induction heating machine can be used to braze different types of heat exchangers, such as copper tube heat exchangers, aluminum tube heat exchangers, plate heat exchangers and strip heat exchangers. We have successfully produced customized handheld heat exchanger induction brazing machines, automatic induction brazing machines for plate heat exchangers, robot induction brazing radiators, and automated induction brazing equipment for electric vehicle aluminum heat sinks for many customers. .

Benefits of brazing heat exchangers with KETCHAN’s induction heating machine

Induction brazing machine can be used for brazing heat exchangers, which are devices that transfer heat between fluids. Heat exchangers are used in various industries, such as automotive, aerospace, electronics, medical, and HVAC. Induction brazing can provide high-quality joints for heat exchanger tubes, fittings, and components.

- Precise and localized heat: Induction brazing can heat only the joint area, without affecting the surrounding material or the base metal. This allows for better control of the brazing temperature and quality and reduces the risk of distortion, metallurgical changes, or oxidation.

- Repeatable and consistent results: Induction brazing can deliver a precise amount of heat to the joint for a specific amount of time, ensuring that the brazing process is repeatable and consistent. Unlike torch brazing, induction brazing is not operator-dependent and can be easily automated.

- Fast and efficient heating cycles: Induction brazing can heat metals very quickly, which can reduce the overall brazing time and increase the throughput. Induction brazing is also more energy efficient, as it only heats the metal that needs to be brazed, and does not require any gas or flame.

- Clean and safe process: Induction brazing is a non-contact process, which means that there is no open flame or risk of combustion. This makes it a safer and cleaner alternative to traditional brazing methods. Induction brazing can also be done in a controlled atmosphere or a vacuum, reducing the need for flux or preventing oxidation.