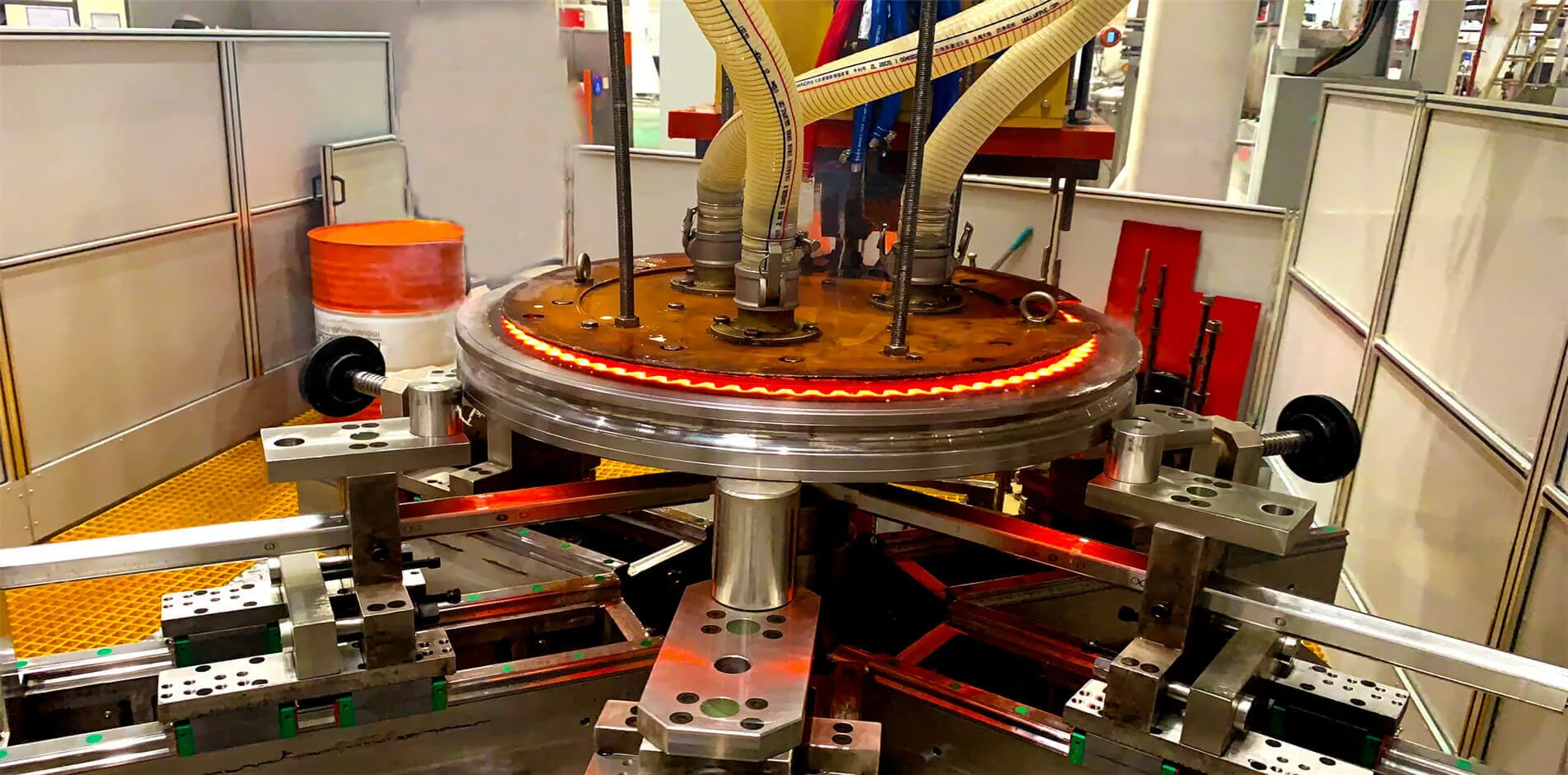

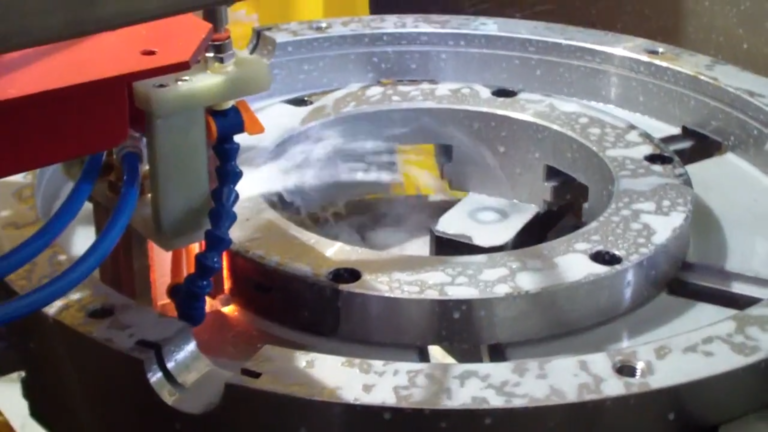

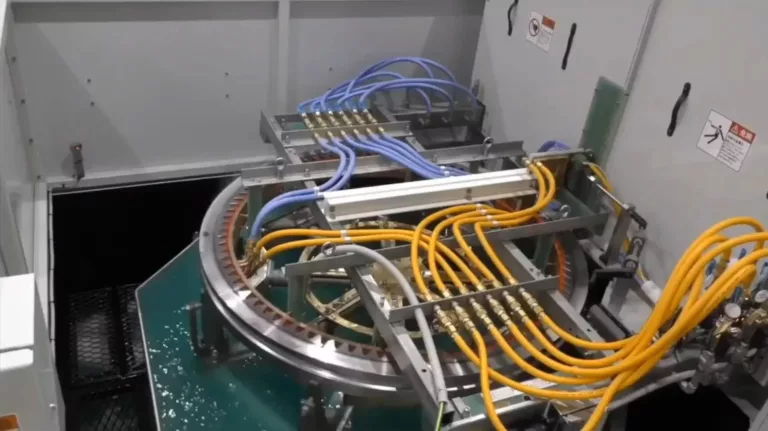

Induction hardening is a type of surface hardening in which a metal part is heated by an alternating magnetic field and then quenched (cooled rapidly). The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction hardening is used to selectively harden areas of a part or assembly without affecting the properties of the part as a whole. Induction hardening is a common process for improving the wear resistance, surface hardness, and fatigue life of steel components such as shafts, gears, springs, and stampings.

How to select the induction hardening frequency?

The heating frequency of an induction hardening machine depends on several factors, such as the size and shape of the workpiece, the required heating depth and pattern, the production rate, and the equipment’s cost and size. Generally, higher frequencies produce shallower heating depths and uniform heat patterns, but they also require more power and may cause more electrodynamic forces and acoustic noise. Lower frequencies produce deeper heating depths and less uniform heat patterns, but they also require less power and may cause less electrodynamic forces and acoustic noise.

For induction hardening, frequencies are split into two groups: medium frequency (MF) and radio frequency (RF). The MF range is typically from 3-50kHz, and RF is from 100-400kHz. MF is suitable for heating large and medium-sized parts with deep case depths, while RF is suitable for heating small and thin parts with shallow case depths. Some examples of induction hardening applications and their typical frequencies are:

- Contour hardening of gears: 3-10 kHz

- Surface hardening of shafts: 10-30 kHz

- Surface hardening of small parts: 100-400 kHz

- Induction brazing of metal workpieces: 100-400 kHz

- Induction melting of small amounts of metal: 100-400 kHz13

To select the best combination of frequency, power, and time to optimize the induction hardening process, a detailed analysis should be performed using computer simulation or experimental testing.

You can send your workpiece to KETCHAN's lab for hardening test, or consult KETCHAN's heat treatment expert for free.

Tags:hardening process, induction hardening, induction hardening equipment, induction hardening guidance, induction hardening heating frequency, induction hardening machine, Induction hardening process, induction hardening solutions, induction hardening tempering, induction heater, induction heating machine, KETCHAN, surface hardening process