What is induction soldering?

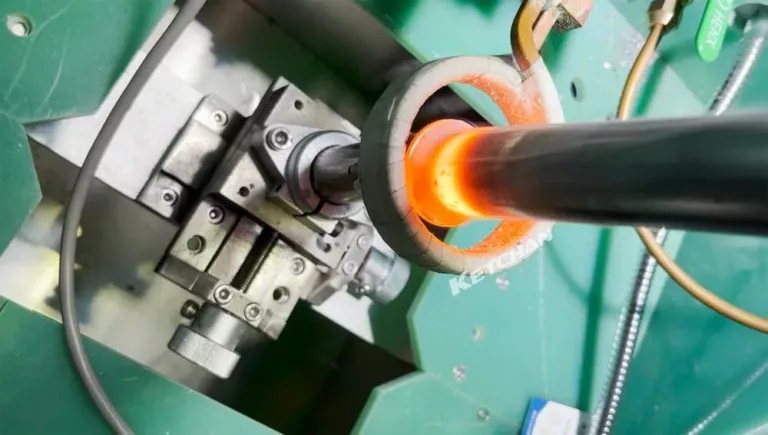

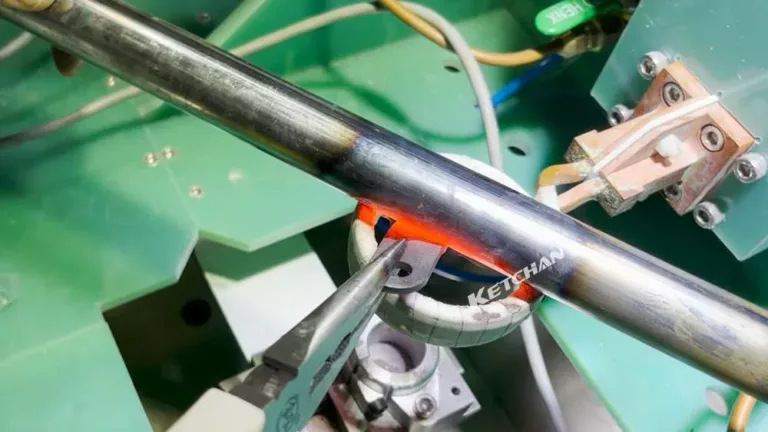

Induction soldering is a process of joining two metal surfaces together using a filler metal called solder. The solder melts at a lower temperature than the metals being joined and forms a strong and durable bond when it cools and solidifies. Induction soldering uses an electromagnetic field to heat the metals and the solder, without using a direct flame or contact. This makes induction soldering fast, precise, and energy-efficient. Induction soldering is commonly used in the electronics industry, as well as in plumbing, metalwork, and jewelry making.

What is an induction soldering machine?

An induction soldering machine is a device that uses an electromagnetic field to heat and join metal parts with a filler metal called solder. Induction soldering machines are fast, precise, and energy-efficient, and they can be used for various applications such as electronics, plumbing, metalwork, and jewelry making. Some of the benefits of induction soldering machines are:

- They do not require a direct flame or contact, which reduces the risk of fire and damage to the parts.

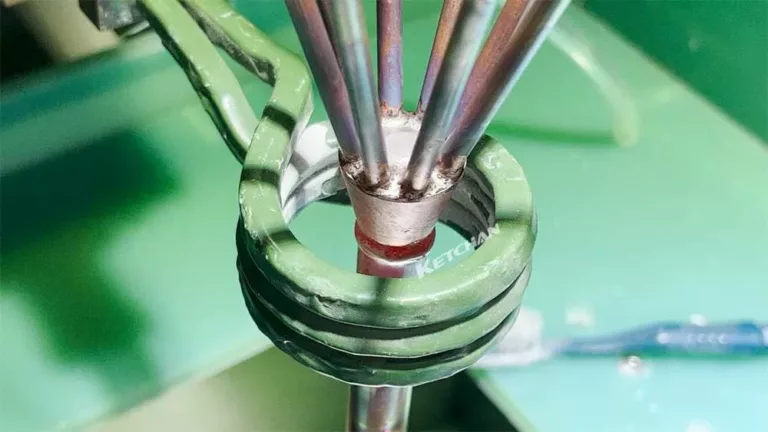

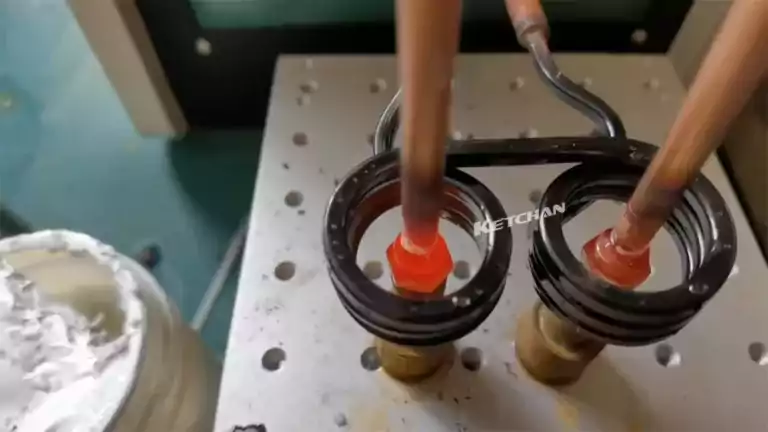

- They can heat the parts uniformly and selectively, which improves the quality and strength of the joints.

- They can control the temperature and duration of the heating process, which prevents overheating and distortion of the parts.

- They can save energy and reduce emissions, as they only heat the parts that need to be soldered.

Induction soldering machine advantages:

Induction soldering machines have many advantages over other methods of soldering, such as using a soldering iron or a torch. Some of the advantages are:

- Speed: Induction soldering machines can heat and join metal parts with solder in a matter of seconds, which increases the productivity and efficiency of the process.

- Precision: Induction soldering machines can target the exact area that needs to be soldered, without affecting the surrounding parts or materials. This improves the quality and strength of the joints, and reduces the risk of damage or distortion.

- Control: Induction soldering machines can adjust the temperature and duration of the heating process, depending on the type and size of the parts and the solder. This prevents overheating and ensures a consistent result every time.

- Safety: Induction soldering machines do not use a direct flame or contact, which reduces the fire hazard and the exposure to harmful fumes or gases. They also save energy and reduce emissions, as they only heat the parts that need to be soldered.

Induction soldering machines are suitable for various applications, such as electronics, plumbing, metalwork, and jewelry making. They can solder different types of metals and alloys, such as copper, steel, aluminum, tin, silver, and lead.

Tags:induction heater, induction heating, induction heating machine, induction soldering, Induction soldering application, induction soldering equipment, induction soldering machine, induction soldering machine advantages, KETCHAN, Manufacturers, price, Suppliers, Zhengzhou KETCHAN, Zhengzhou KETCHAN Electronic