What is induction soldering?

Induction soldering works by using a precise electromagnetic field to heat two or more electrically conductive materials in order to join them with a filler material that melts at a temperature below the melting point of the joined materials. The electromagnetic field (induction heating) is generated by an induction coil that surrounds the workpieces and transfers heat to them by inducing eddy currents within them. The filler material, usually a solder alloy, is placed between the workpieces and melts when heated by the induction coil. The molten solder then flows into the joint interface and solidifies when cooled, forming a strong bond between the workpieces. Induction soldering has many benefits, such as fast heating cycles, reduced error potential, enhanced control, and consistent quality.

What are the benefits of induction soldering?

- It meets tight production tolerances with precise localized heat to small areas creating pinpoint accuracy.

- It increases production rates with faster heating cycles.

- It reduces defect rates with repeatable, reliable heat.

- It eliminates variability from operator to operator, shift-to-shift.

- It maintains the metallurgical characteristics of the individual metals

- It avoids thermal stress and damage to surrounding substrates.

- It is more energy efficient and environmentally friendly than torch or flame soldering.

How to do the Induction Precision Soldering process?

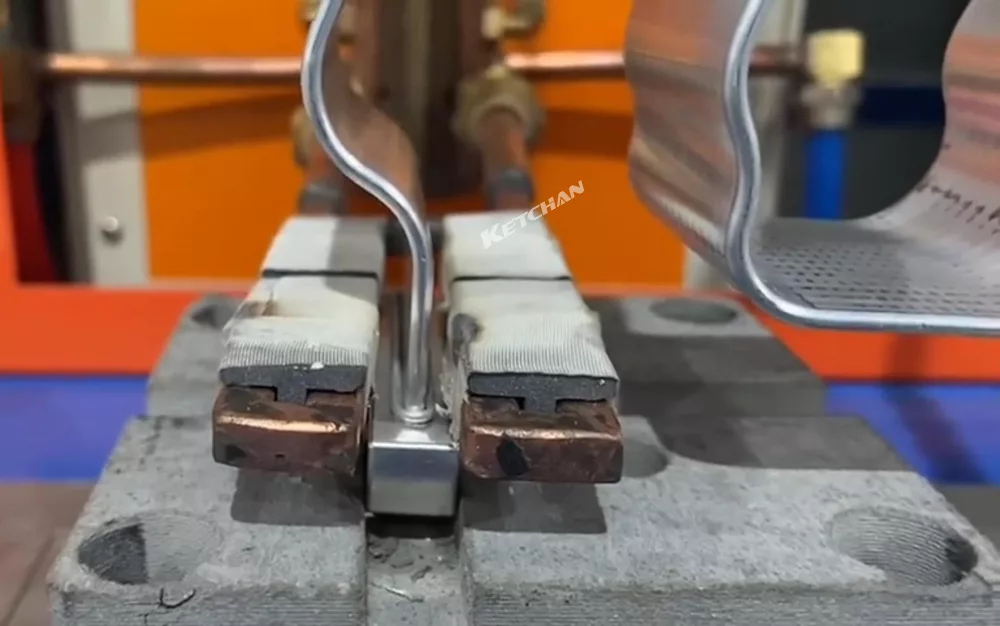

- Prepare the workpieces and the filler material (solder) by cleaning them and applying flux if needed.

- Place the workpieces and the filler material in the desired position and alignment.

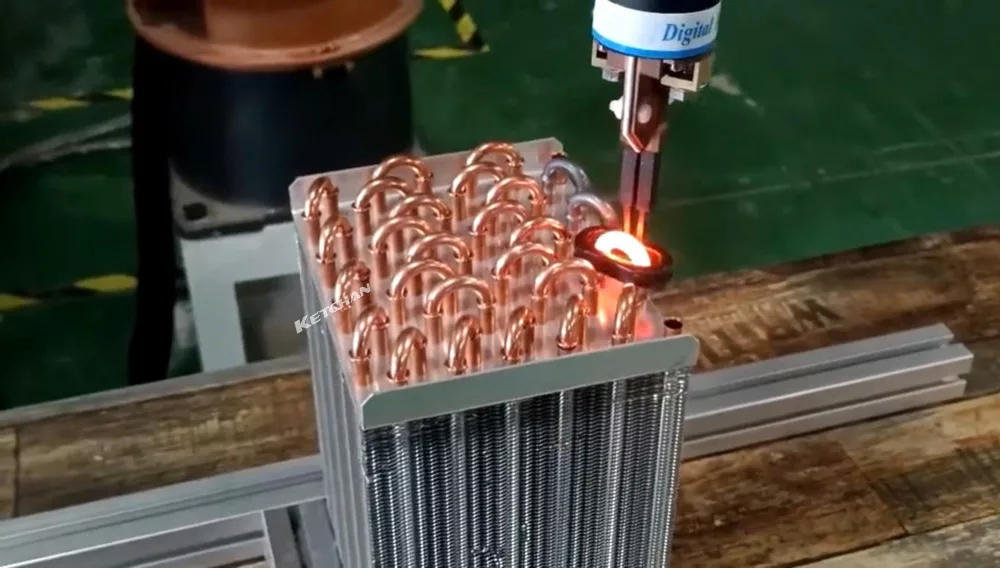

- Place an induction coil around the workpieces and connect it to a power unit and a work head.

- Turn on the power unit and adjust the power and frequency settings according to the application requirements.

- The induction coil will generate an electromagnetic field that will induce eddy currents

You can find more information on how to select an induction soldering machine from our induction heating experts!

KETHCAN Induction Heating Technology