Induction brazing coils are devices that are used to heat metal parts for brazing, which is a process of joining two or more materials with a filler metal that has a lower melting point than the base materials. Induction brazing coils generate an electromagnetic field that induces currents in the conductive material of the workpiece, causing it to heat up rapidly and melt the filler metal. Induction brazing coils can have different shapes and sizes, depending on the application and the geometry of the parts to be brazed. Some common types of induction brazing coils are helical, pancake, split, channel, and inside coils. Induction brazing has many advantages over other methods of brazing, such as torch brazing or furnace brazing. Some of these advantages are:

- Efficiency: Induction brazing only heats the area of the assembly that needs to be brazed, saving energy and time.

- Repeatability: Induction brazing can produce consistent and high-quality joints every time, with precise control over the temperature and heating time.

- Safety: Induction brazing does not use any open flame or hot furnace, reducing the risk of fire and burns.

- Integration: Induction brazing can be easily integrated into a lean manufacturing process, with small footprint and flexible coil design.

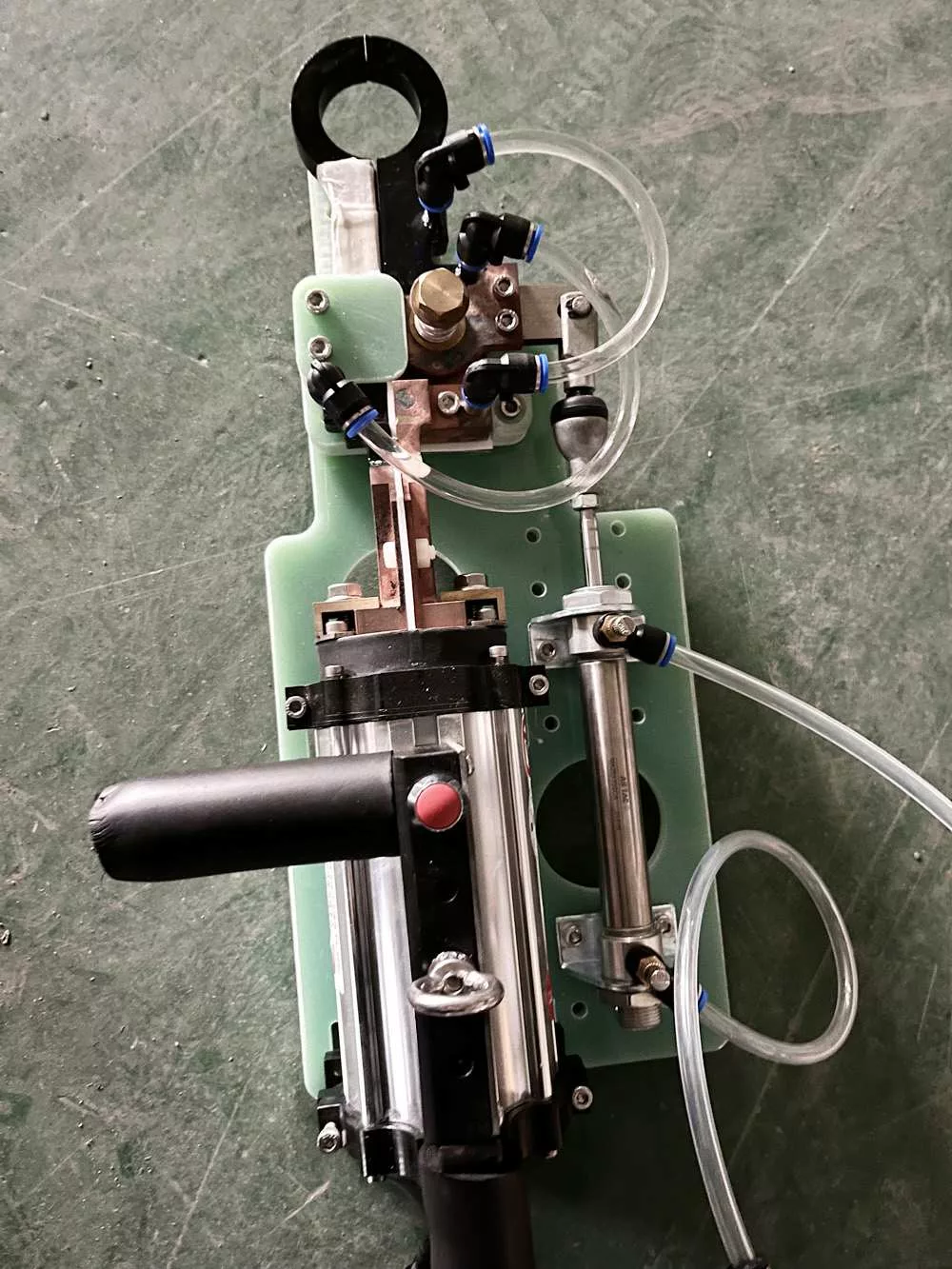

An automatic opening and closing induction coil is a type of induction coil that can switch the current in the primary coil on and off automatically, without the need for an external interrupter. This can be achieved by using a relay or a transistor circuit that is controlled by the feedback from the secondary coil. When the secondary coil produces a high voltage, it triggers the relay or the transistor to cut off the current in the primary coil, thus collapsing the magnetic field and generating another high voltage pulse in the secondary coil. This process repeats itself at a high frequency, creating a series of sparks across the terminals of the secondary coil. The automatic opening and closing induction coil is suitable for relatively long workpieces. After the welding is completed, the induction coil is opened to facilitate the removal of the workpiece.

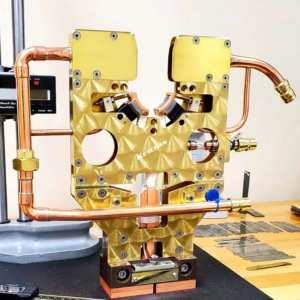

Induction brazing welding product display