What is air cooled industrial chiller?

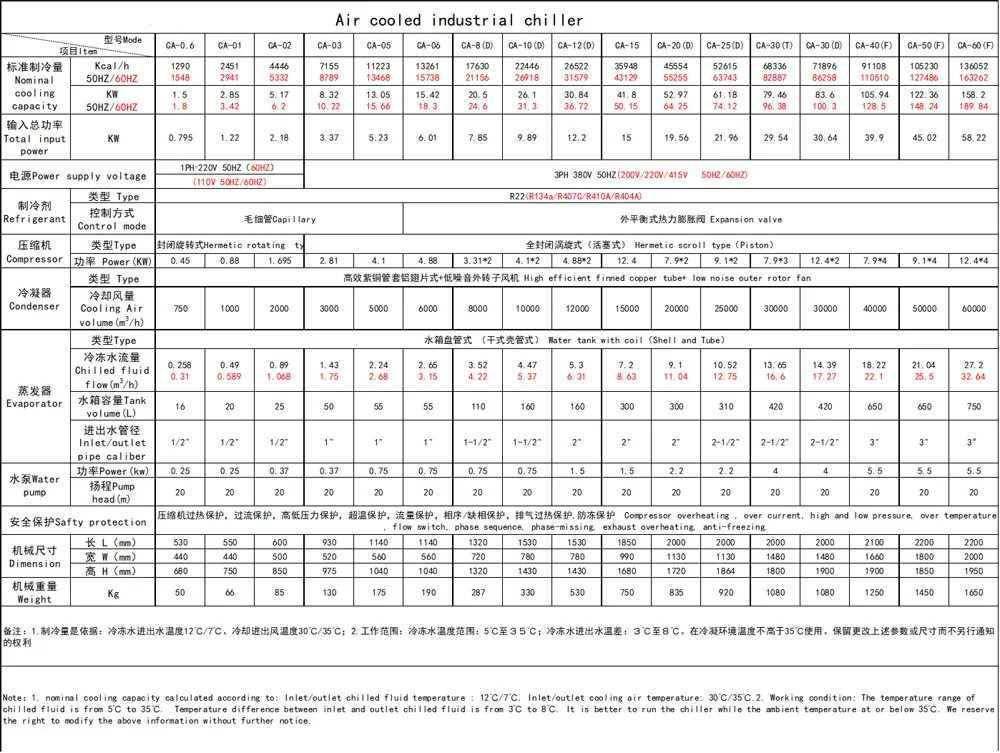

Air cooled industrial chiller is a kind of cooling water equipment that can supply constant temperature, constant current, and constant pressure. The operation principle of air cooled industrial chiller is to inject a certain amount of water into the machine water tank first, cool the water through the small cold water mechanism cooling system, and then send low-temperature cooling water into the equipment to be cooled by the pump. The frozen water of air cooled chiller will take the heat away and return to the water tank after the temperature rises, and reach the cooling effect.

Cooling water temperature can be adjusted according to requirements, long-term use can save water. Therefore, this air cooled water chiller is a standard energy-saving equipment, is designed for supporting industrial induction heating equipment and induction coils cooling. it is delicate, simple, and suitable and is the ideal supporting product for industrial heating equipment cooling.

What are the components of air-cooled industrial chiller?

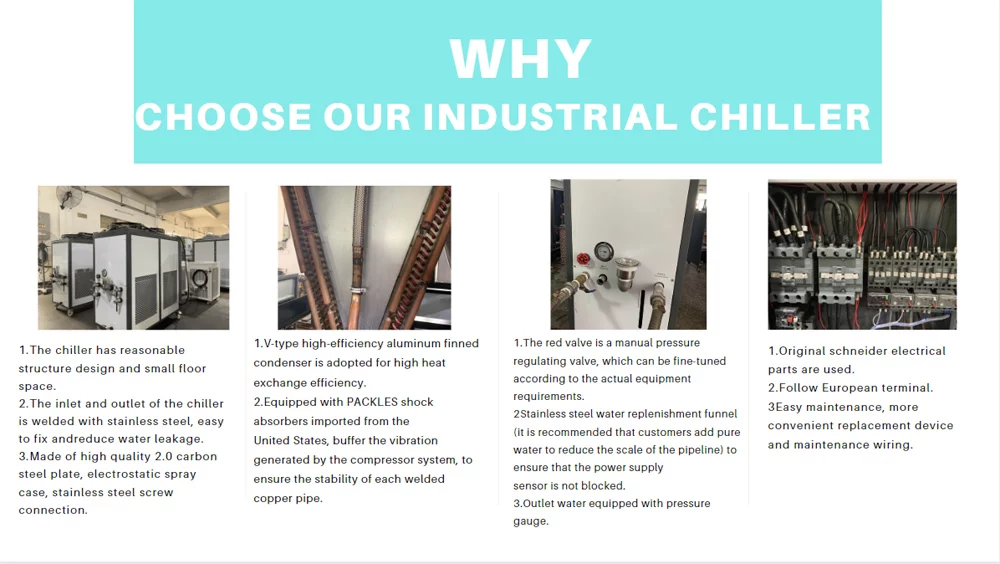

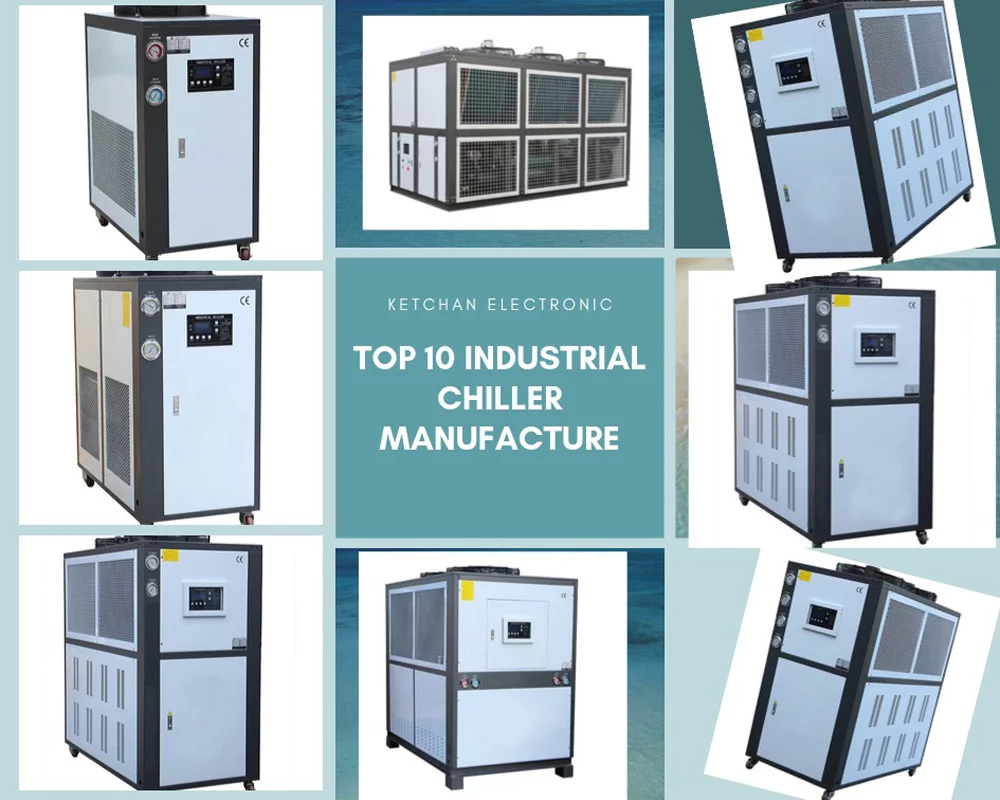

Our air-cooled industrial chillers are widely used in some famous international industries because of their beautiful looks and also stable functions. And the main parts of our air-cooled water chiller are as follows:

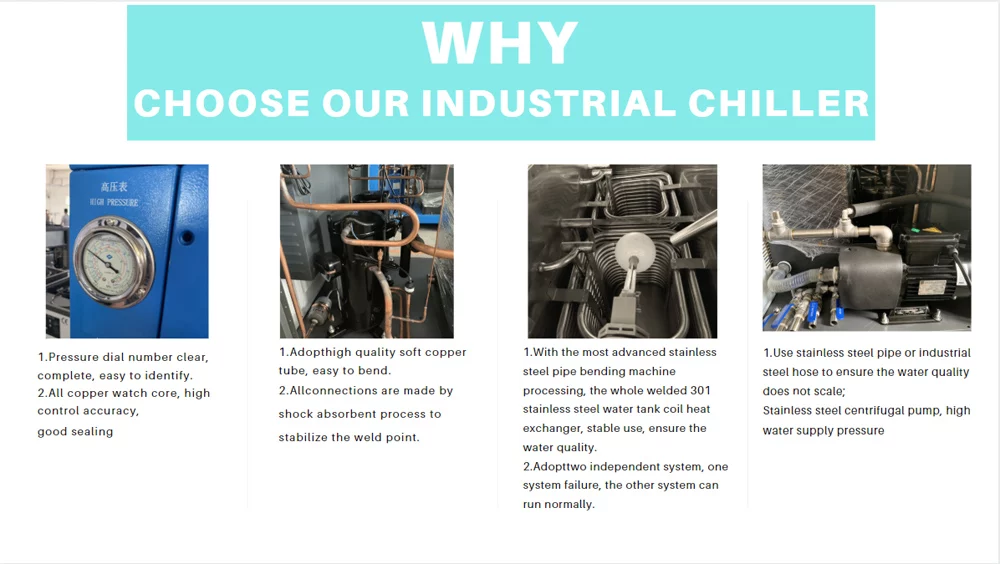

- Compressor: It adopts fully enclosed scroll compressors such as Daikin, Sanyo, Panasonic, COPELAND, and GMCC supporting condenser and evaporator made of high quality and high-efficiency copper tube and world-renowned brand components, so that the industrial chiller has the advantages of small volume, low noise, high energy, long service life, and easy operation.

- Evaporator: The evaporator copper pipe adopts internal and external screw reinforced pipe. The surface of the copper tube is threaded, the outer surface of the copper tube is smooth and the cooling effect is good. The evaporator barrel body is insulated by a 25mm thick PE insulation board, which does not condense and has a less cold loss.

- Condenser: The condenser adopts the copper tube imported from abroad, which is processed into a trapezoidal low-ribbed tube to enhance the heat transfer capacity. The surface of the copper tube is smooth, which reduces the water pressure and is easy to clean and maintain.

- Protective device: The protection system devices include: compressor delay start protector, overload protector, high and low-pressure protector, temperature control switch, antifreeze switch, fuse plug, electronic time protection safety valve, compressor overheat protector, compressor frequent start protector and abnormal indicator light to ensure the normal operation of the chiller unit.

- Control system: Our company has developed a high-intelligence PLC, PC-level computer control system, which can be used for remote monitoring and control, and has multiple functions such as automatic loading and unloading, timing switch machine, and recording the cause of failure; simple operation, the host is connected to the power supply. The failure rate is low, the safety factor is high, the installation is simple, and the system control can be adjusted immediately, which is intuitive and reliable.

- Freezer Accessories: All refrigeration accessories are selected from the world’s top brands SPORLAN (American Sporland), ALCO (American Eco), DANFOSS (Danfoss, Denmark), etc., with excellent performance, safety, and environmental protection.

- Fan: Optional imported European CIE fans, or domestic famous brand FULIHUA fans, Marr fans, etc. Internationally advanced rotor design, imported aluminum-magnesium alloy, and Japanese imported Teviron fans, have a long service life, low noise, high efficiency, rain and snow resistance, and high-temperature resistance.

How to select the suitable air-cooled industrial chiller?

What is air cooled industrial chiller applications?

Air cooled industrial chillers are widely used in plastics, electronic manufacturing, electroplating, medicine and chemical industry, ultrasonic cooling, printing, and other industrial production. Air cooled chillers can precisely control the temperature required in modern industrial mechanized production, thereby greatly improving production efficiency and product quality. The air-cooled industrial chiller is easy to operate, reasonable in design, excellent in quality, and complete in models. It is an indispensable companion for modern industrial production.

Why choose KETCHAN's air cooled industrial chiller?