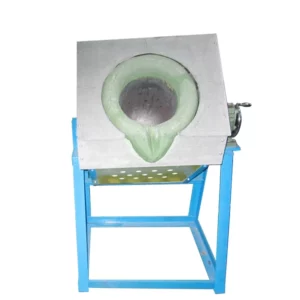

Introduction of Aluminum melting furnace:

The aluminum melting machine is composed of a frequency conversion power supply, melting furnace body, cooling tower, dumping device, and alarm system. It USES SCR or IGBT to convert the three-phase current into the DC of medium and high frequency, and then passes through the filter for filtering, and finally passes through the inverter to turn the DC into the AC supply load of a certain frequency. Our factory’s latest constant power (energy saving) intermediate frequency melting furnace has been widely praised by customers after long-term production practice and has been improved on the original basis, making its performance more excellent. An aluminum shell furnace is generally used for smelting less than 1T, compared with the traditional electric furnace saving 10%, simple maintenance. Easy to change furnace, high production efficiency. Compared with steel shell furnaces cheaper, and low production cost.

Aluminum melting furnace features:

- Low energy consumption, high efficiency, no pollution, easy control, low harmonic.

- No flame design, safe production. Energy conservation and environmental protection.

- Rapid temperature rise, self-stirring function, melting temperature, and metal composition uniform.

- Low burning loss of metal elements, less slag, good quality of liquid metal.

- High power factor. During the whole machine operation, the power factor can reach more than 98%.

- High startup success rate, any load, startup success rate is 100%.

- One furnace multi-purpose, improves production efficiency.

- The motherboard adopts a modular design, plug, and play, is easy to maintain.

- The unique water-cooled cable connection minimizes the displacement of water-cooled cable when pouring into the furnace and improves its service life.

- Strong coil support design eliminates the possibility of an inter-turn short circuit, greatly extending the induction coil service life.

- Use cooling rings at the top and bottom to extend lining life.

- This equipment adopts high-performance insulating material.

- It can be equipped with a leakage alarm device.

Aluminum melting furnace parameters:

| Aluminum melting(700℃) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Capacity(t) | 0.4 | 0.6 | 0.8 | 1.2 | 1.6 | 2 | 3 | 5 |

| Power(Kw) | 200 | 300 | 400 | 600 | 800 | 1000 | 1500 | 2500 |

| Frequency(Hz) | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| Melting rate(t/h) | 0.38 | 0.63 | 0.74 | 1.1 | 1.57 | 1.94 | 2.94 | 4.83 |

| Melting consumption(kwh/t) | 525 | 525 | 525 | 520 | 520 | 500 | 500 | 500 |

| Cooling water flow(m³/h) | 5 | 8 | 9 | 12 | 15 | 20 | 26 | 45 |

Our services:

- Free technical advice, free samples.

- The machine is guaranteed for one year. Lifetime after-sales support.

- Provide overseas after-sales support, on-site installation, and commissioning services.

- All products are 100% debugged and inspected before delivery.

- Professional export packing and lengthy sea voyages also need not worry.

- Products exported to the European Union, the United States, Australia, and other developed regions have quality certification requirements.

Application of Aluminum melting furnace:

According to the characteristics of nonferrous metals, the rapid melting furnace, intermediate frequency induction copper melting furnace, aluminum melting equipment, and lead melting furnace is specially designed with advanced technology for melting and heat preservation of nonferrous metals. It adopts a reducer or manual tilting furnace, a square shell furnace structure, belongs to traditional equipment, is simple structure, easy to operate. If melting nonferrous metal can achieve high efficiency, save electricity, reduce pollution, less metal burning loss, high molten liquid quality. Thus the cost is reduced, the product quality is improved, and the market competitiveness is enhanced.

The special furnace has been widely used in die casting, art casting, special casting, precision casting, and other industries, can be for cars, motorcycles, valves, water pumps, art, hardware decoration casting excellent parts. More intermediate frequency induction zinc oxide, silicon carbide, and other special materials melting furnaces can be customized according to user requirements.