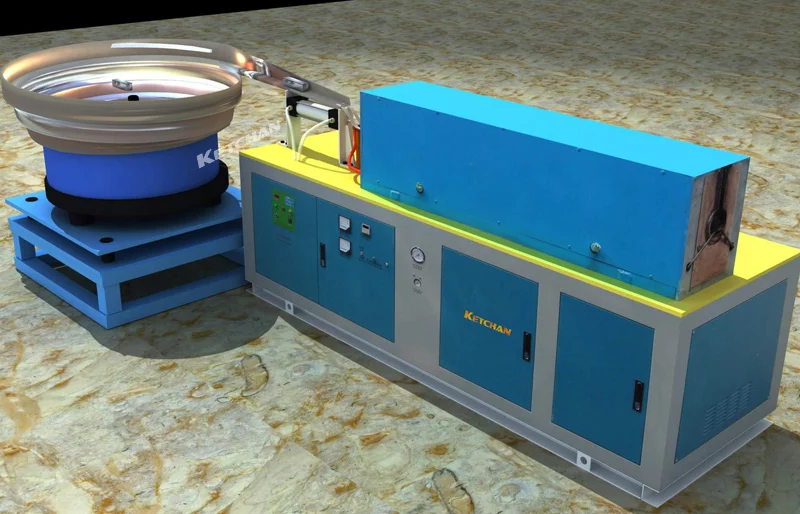

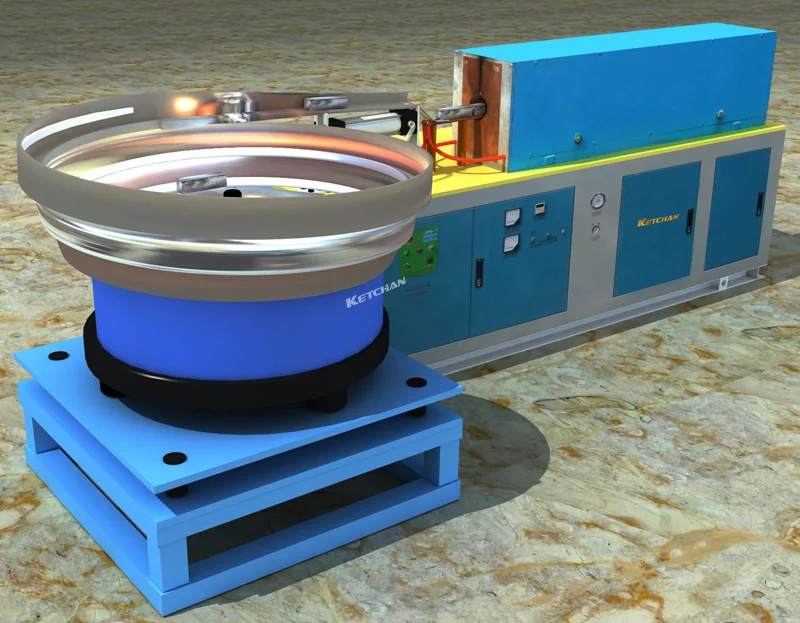

What is ZHENGZHOU KETCHAN automatic forging equipment features?

- Fast heating speed without oxidation: The automatic forging equipment heating method has a fast heating speed, less oxidation, and decarburization, and saves at least 20-50 kg of steel raw materials per ton compared with a coal furnace, and its material utilization rate can reach 95%.

- Uniform heating results and prolonged life: The heat generated by induction heating in the workpiece itself is evenly heated, and the core table temperature difference is very small, so as to prolong the life of the forging die, and forging surface roughness is less than 50UM.

- Accurate temperature control, stable operation: Medium frequency automatic forging equipment adopts originally imported accessories, equipment 0 failure, can work 24 hours. The application of a temperature control system can accurately control the temperature, and improve the quality of products and pass rate.

- High production efficiency, high production efficiency: The automatic forging equipment is equipped with an automatic feeding machine and fast discharging machine, flexible in and out of material, can realize mechanization and automatic production line, reduce the dynamic production line production, reduce the labor intensity.

- Environmental protection, less pollution, improve image: Compared with the coal stove, the workers will no longer be baked and smoked by the coal stove, the working environment is superior, more environmental protection requirements, and establish the external image of the company.

What is the automatic forging equipment application?

- Application of induction forging production line for ribbed reinforcement;

- Induction forging all kinds of bars, round bar, square bar, and all kinds of different billets online automatic induction forging.

- Standard parts (nuts and bolts) online induction forging process.

- All kinds of different pipelines local induction heating hot forging.

- Cold is drawn solid steel hot forging, hot heading of cold drawn seamless steel pipe.

- Drill pipeline end induction heating forging.

- Automative parts induction heating forming.

- Brass bar online induction heating forging.

- Steel ball and steel column automatic forging equipment.

- Railway accessories rivet, spring bar, spike hot forging molding.

- Induction heating forging supporting accessories such as spring and U-type cable.

How can I find the suitable automatic forging equipment?

As one of the leading automatic forging equipment manufacturers in China, we have a professional induction forging engineers team. And also we have thousands of different induction forging application cases for reference, so you can please let me know your heating parts material, size, and heating speed requests, then we can calcaulate which induction forging system power you need and also as per your automation level requests, we can suggest the suitable automatic forging equipment for your choice.

What is your after-sales service?

- Technical after-sales service: we have professional automatic forging equipment engineers to follow the machine technical service.

- Our automatic forging equipment service period is 12 months.

- During the warranty period, during the automatic forging equipment normal using period, if there are quality problems, the seller is responsible for the damaged parts exchange. If the problems are caused by improper operation, the seller is responsible for guiding the buyer to maintain the machine well and also take the spare parts’ basic costs.