What is ZHENGZHOU KETCHAN's induction melting furnace?

Our Induction melting furnace is mainly used in the jewelry industry and laboratory research units. ZHENGZHOU KETCHAN developed and produced the induction heating power supply and induction smelting furnace body independently, saving outsourcing costs and offering better value for users. Strong technical strength ensures the induction melting equipment quality is more stable, it is your ideal choice! Can be used for pure graphite crucible and quartz crucible rapid induction melting, the melting time is short, high thermal efficiency, and easy to operate. At the same time, the heating power supply has an electromagnetic stirring function, and the metal can be melted evenly without a stirring rod. The price is more competitive than other supporting manufacturers and cost-effective!

Why use an induction melting furnace?

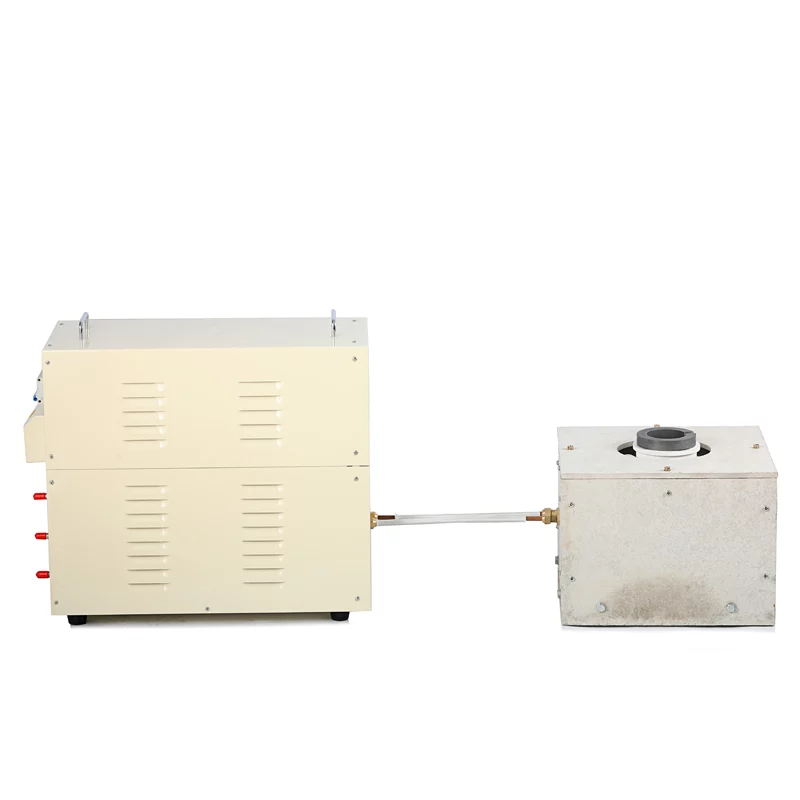

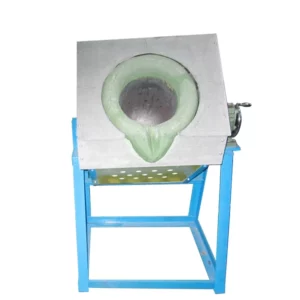

Induction melting furnace equipment is composed of a medium frequency magnetic induction heating power supply, mechanical equipment tilting melting furnace, and compensation capacitor. Its main characteristics are as follows:

- Installation, and practical operation is very convenient, you can learn it well in a few minutes;

- The induction melting furnace is of small size, lightweight, mobile, and covers an area of less than 1 square meter;

- 24 hours continuous induction smelting capacity;

- ZHENGZHOU KETCHAN’s induction melting furnace power from 5KW-200kw, different specifications, different induction melting volume, and the machine power choice are different.

- It is suitable for melting all kinds of metal materials below 20Kg, especially for induction heating or melting of gold, silver, copper, platinum, powder metal, etc.

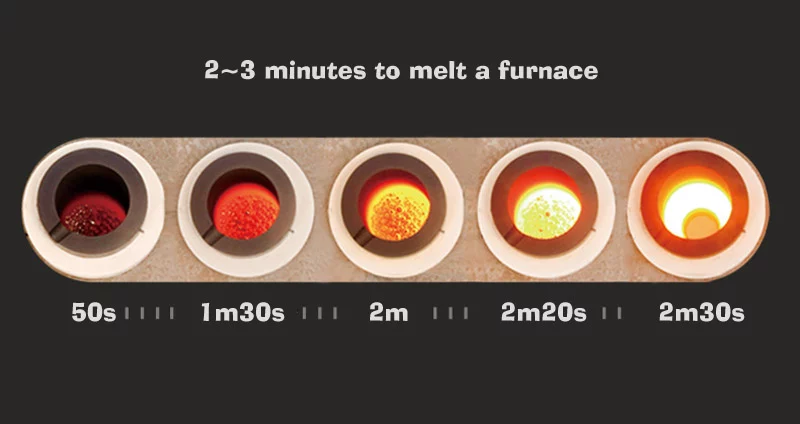

- Mostly the melting time is controlled in 1-15 minutes.

- Small size, lightweight, easy to move and handle;

- Energy-saving, power consumption depends on the heating of different workpieces, it is relative to the same power tube high-frequency machine energy saving three quarters, relative to other heating methods (such as gas, electric furnace, gas furnace, coking coal, etc.) cost is also greatly reduced;

- Safety operation and no high voltage.

- No preheating and super-fast heating speed, greatly reduce the deformation degree of the work.

- With the electromagnetic stirring function, no need to add a stirring bar;

- Can equip with temperature controller, display and control metal temperature, so that to make sure get the high quality melting products.

How to Choose the induction melting furnace cooling machine?

Every induction melting furnace needs a cooling water device, choosing the appropriate cooling water device can effectively prolong the service life of the equipment

- Choose the simple circulating water tank to cool the induction melting furnace, and with this method features are low cost, unable to control water temperature; Water pump selection: recommended to use booster pump: power 550W-750W, Lift height is 30 and 50 meters self-priming pump; Water tank: 1-m3;

- We suggest choosing an industrial chiller to cool the induction melting furnace, In this method, the basic cost is higher, but it has the self-cooling functions and can control the cooling water temperature very well.

How to choose the suitable induction melting furnace crucible?

Crucible is an important part of the intermediate frequency induction melting furnace. It is not only used for holding metal melt for smelting but also plays the role of heat insulation, insulation, and energy transfer. The most commonly used crucibles are Magnesia crucible, graphite crucible, and white stone crucible three materials of the durable crucibles, suitable for different material induction smelting jobs.

What are the components of the complete induction melting furnace?

The standard induction melting system normally includes the following parts, they are induction melting power supply, induction melting furnace and the following parts.