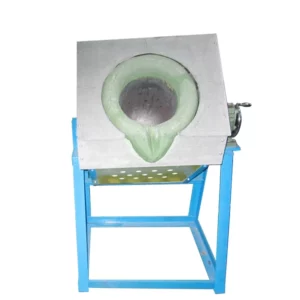

ZHENGZHOU KETCHAN Scrap steel melting furnace

Medium frequency scrap steel melting furnace is a kind of three-phase power frequency current into a single-phase medium frequency current frequency conversion device, through electromagnetic field induction metal eddy current loss, and achieve the purpose of induction heating and melting. Used for metal induction smelting, heating, and heat preservation of ferrous or non-ferrous metals and alloys such as iron and steel, copper, aluminum, zinc, and lead. Mainly used in casting and smelting industries.

One of the ZHENGZHOU KETCHAN new 1+2 series intermediate frequency scrap steel melting furnaces is equipped with an intermediate frequency power supply that drags two furnace bodies to work simultaneously. The power distribution between the two furnace bodies can be realized by adjusting the power knob (or digital operation screen). The total power of the intermediate frequency power supply can be arbitrarily distributed between two furnace bodies to achieve the effect of melting one furnace body and keeping the other one warm. Continuous smelting mode, greatly improves the production, energy-saving practical, deeply accepted and loved by the majority of our customers.

High frequency induction heat treatment machine heating hardening principle is: Place the workpiece into the induction coil which is wound with a copper tube. After entering high frequency AC, the workpiece surface generates the same frequency induction current. The workpiece surface can be heated quickly (within a few seconds can raise the temperature of 800 ~ 1000℃, the core is still close to the indoor temperature) and then quickly spray (dip) cooling water (or spray oil cooling) for induction quenching working, make the surface layer or part of the workpiece reach the required induction hardening depth and hardness.

Why choose ZHENGZHOU KETCHAN scrap steel melting furnace?

- Zero-voltage scanning soft start mode, can start or stop at any time, no impact on the power supply;

- Fast melting (single furnace melting time can be less than 30 minutes, low production cost (ton power consumption is less than 550 degrees); Pollution is small;

- The scrap steel melting furnace can be melted directly from the cold furnace, the solution can be emptied completely, and it is convenient to replace the melting material.

- Flexible and convenient power adjustment, continuous smooth adjustment; Uniform temperature easy to control, less oxidation burning loss, uniform metal composition;

- The furnace shell adopts a cast aluminum alloy or steel structure, which covers a small area; The scrap steel melting furnace body is easy to turn over and dump, manual, electric, hydraulic dumping furnaces can be selected

- This scrap steel melting furnace system can realize automatic remote control, including a PLC programmable controller, HMI man-machine interface or industrial control computer system and industrial control configuration software, and all kinds of sensors. It can realize automatic constant temperature, automatic oven drying, an automatic operation such as an anti-penetration furnace alarm, safer and more convenient to use!

- Automatic constant temperature function: the range of furnace water temperature requirements can be set in advance, and the purpose of automatic constant temperature can be realized by a one-button startup. Compared with the traditional manual temperature control, the automatic constant temperature function will save time and trouble and be more sensitive and accurate. The furnace water temperature is easier to control, the oxidation burning loss is less, and the quality of the products is better.

- Automatic drying furnace function: Drying furnace is a relatively complex and long time curve heating process, to extend the service life of medium frequency scrap steel melting furnace, and reduce production costs, the correct furnace building process is very important. Our company’s innovative automatic furnace function, according to different furnace lining refractory furnace temperature requirements, to pre-set the time and temperature required by different furnace stages; According to the value of PLC pre-setting time and temperature, one-key start, automatic matching, and stepless control of the size of the intermediate frequency power, control of heating speed, prevent the furnace lining crack, and achieve the purpose of automatic curve oven. That is to avoid manual misoperation at the same time also reduce the labor time and intensity of workers.

- Prevent wear furnace alarm function: prevent alarm system working principle is: wear furnace chamber use time to a certain degree, the wall will gradually thinning, intermediate frequency electric current will vary according to the furnace wall, after the current rate reaches the preset value will make an alarm to remind in advance, then automatically cut off the power and predict wear furnace and achieve the goal of safe production in advance.

ZHENGZHOU KETCHAN scrap steel melting furnace model choice

| Scrap steel melting (1450℃) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity(t) | 0.5 | 1 | 1.5 | 2 | 3 | 4 | 5 | 7 | 10 | 12 | 15 | 20 | 30 |

| Power(Kw) | 400 | 600 | 800 | 1000 | 1500 | 2000 | 2500 | 3000 | 5000 | 6000 | 8000 | 15000 | 20000 |

| Frequency(Hz) | 500 | 500 | 500 | 500 | 500 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

| Melting rate(t/h) | 0.6 | 1.08 | 1.4 | 1.89 | 2.94 | 3.78 | 4.62 | 5.67 | 9.76 | 11.76 | 16 | 30 | 40 |

| Melting consumption(kwh/t) | 525 | 525 | 525 | 520 | 520 | 510 | 500 | 500 | 490 | 490 | 500 | 500 | 500 |

| Cooling water flow(m³/h) | 5 | 7 | 10 | 13 | 18 | 25 | 30 | 34 | 55 | 62 | 72 | 92 | 100 |