1. Why choose the KETCHAN's silver melting furnace?

- ZHENGZHOU KETCHAN’s IGBT silver melting furnace is with digital temperature control systems.

- Integrated circuit, intelligent power saving.

- Direct drive medium frequency induction coil for fast working.

- Can 24 hours non-stop working.

- One key operation is simple and convenient.

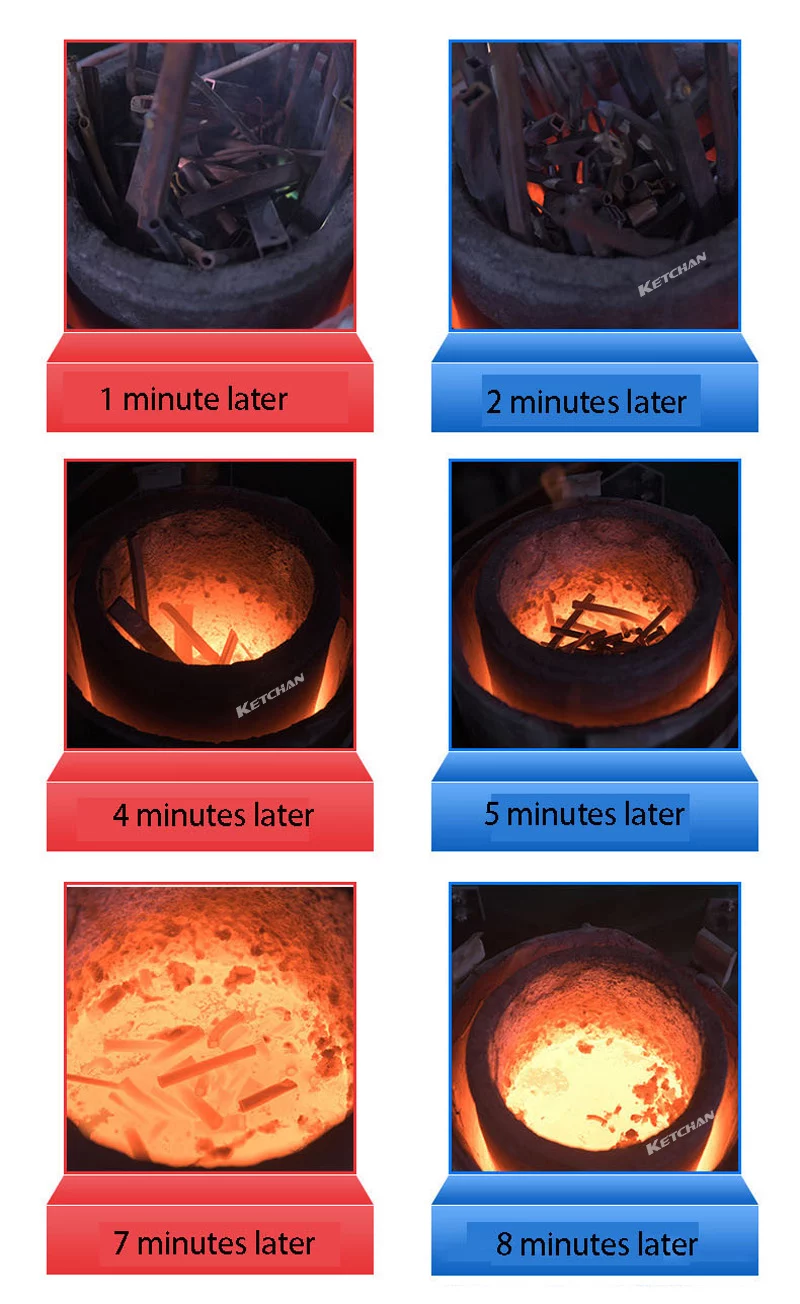

Silver Melting Furnace melting process

Silver melting furnace technical data

These years, we do a lot of different types of silver melting furnaces and conclude the following induction melting furnace data sheet for your reference. When you meet different materials or request different induction melting furnace models, please contact us for customizing. Thanks.

| Model | Melting material | Temperature (℃) | Melting Weight(KG) | Melting time | Crucible material |

|---|---|---|---|---|---|

| KRZ-15R | Aluminium | 850 | 3 | 15 minutes | Clay graphite |

| 6 | 30 minutes | ||||

| Brass(Silver) | 1100 | 5 | 15 minutes | ||

| 10 | 25 minutes | ||||

| Copper | 1300 | 5 | 25 minutes | ||

| 10 | 40 minutes | ||||

| KQZ-25R | Aluminium | 850 | 6 | 20 minutes | Clay graphite |

| 20 | 25 minutes | ||||

| Brass(Silver) | 1100 | 10 | 15 minutes | ||

| 20 | 25 minutes | ||||

| Copper | 1300 | 10 | 25 minutes | ||

| Iron and steel | 1600 | 5 | 20 minutes | Magnesia | |

| KQZ-35R | Aluminium | 850 | 10 | 20 minutes | Clay graphite |

| 12 | 30 minutes | ||||

| Brass(Silver) | 1100 | 30 | 30 minutes | ||

| Copper | 1300 | 30 | 40 minutes | ||

| Iron and steel | 1600 | 10 | 25 minutes | Magnesia | |

| KQZ-45R | Aluminium | 800 | 18 | 30 minutes | Clay graphite |

| Brass(Silver) | 1100 | 50 | 40 minutes | ||

| Copper | 1300 | 50 | 50 minutes | Silicon carbide | |

| Iron and steel | 1600 | 20 | 30 minutes | Magnesia | |

| KQZ-70R | Aluminium | 850 | 35 | 35minutes | Silicon carbide |

| 50 | 45 minutes | ||||

| Brass(Silver) | 1100 | 100 | 50 minutes | ||

| Copper | 1300 | 100 | 80 minutes | ||

| Iron and steel | 1600 | 30 | 30 minutes | Magnesia | |

| KQZ-90R | Aluminium | 850 | 50 | 50 minutes | Silicon carbide |

| 70 | 70 minutes | ||||

| Brass(Silver) | 1100 | 150 | 60 minutes | ||

| Copper | 1300 | 150 | 80 minutes | ||

| Iron and steel | 1600 | 50 | 45 minutes | Magnesia | |

| KQZ-110R | Aluminium | 850 | 100 | 60 minutes | Silicon carbide |

| 150 | 90 minutes | ||||

| Brass(Silver) | 1100 | 150 | 45 minutes | ||

| Copper | 1300 | 150 | 80 minutes | ||

| Iron and steel | 1600 | 80 | 45 minutes | Magnesia | |

| KRZ-160R | Aluminium | 850 | 150 | 80 minutes | Silicon carbide |

| 200 | 120 minutes | ||||

| Brass(Silver) | 1100 | 200 | 45 minutes | ||

| 300 | 70 minutes | ||||

| Copper | 1300 | 150 | 60 minutes | ||

| 200 | 90 minutes | ||||

| 300 | 120 minutes | ||||

| Iron and steel | 1600 | 100 | 40 minutes | magnesia | |

| 150 | 60 minutes |

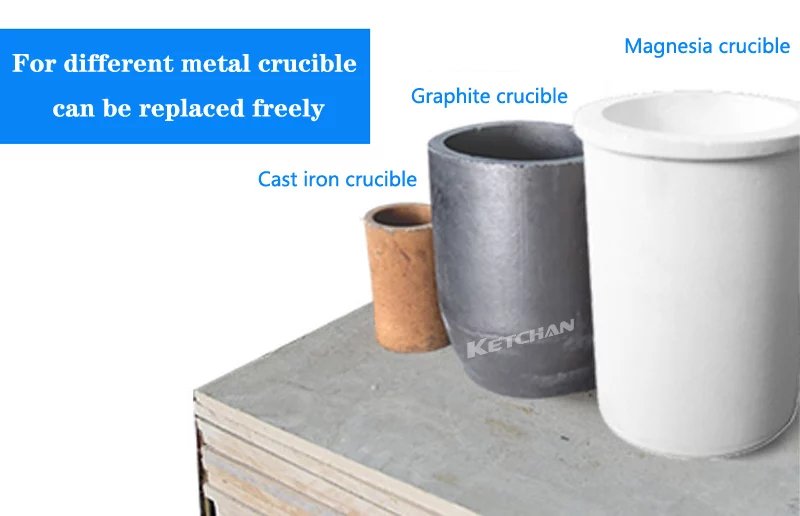

How to choose the suitable melting crucible?

In order to improve the silver melting furnace’s working efficiency and serving life, we will choose durable crucibles to save your costs a lot. Below I will show you how to choose a suitable induction melting crucible:

- Magnesia crucible: It is mainly used for smelting iron and steel.

- Graphite crucible: It is mainly used for the smelting of non-ferrous metals such as copper, aluminum, silver, gold, and silver crucible with pure graphite.

- Whitestone crucible: It is mainly used for high melting point metal melting such as titanium alloy, and nickel alloy.