Summary

Wire induction heat treatment machine series induction heating machine tools are suitable for induction heat treatment of various rod parts, wire parts, plate parts induction heat treatment production lines. The complete wire induction heat treatment machine is consist of a machine tool bed, IGBT induction heating power supply, high temperature induction tempering power supply, workpiece loading, and unloading assembly, heating inductor, tempering inductor, cooling system, etc. Adopt a PLC control system to realize workpieces’ automatic feeding, feeding, heating, parameter monitoring, and recording control. It has the advantages of fast heat treatment speed, less oxide scale, and energy saving.

What is wire induction heat treatment machine applications?

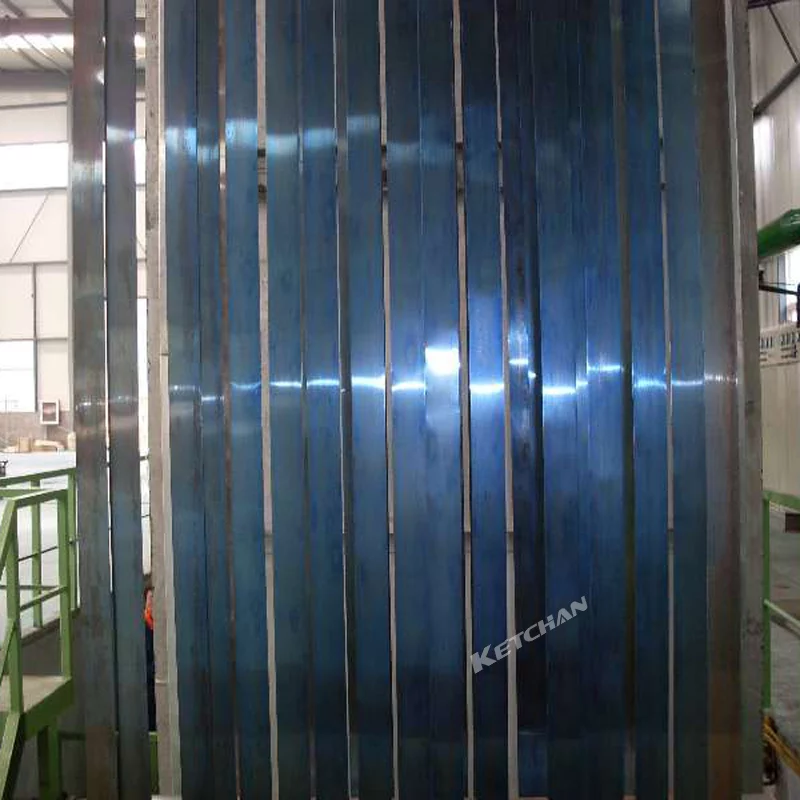

- Application: steel wire, copper wire, steel stripe, steel plate, copper strip, aluminum plate, steel rods, etc.

- Workpiece parameters: diameter 0.5-20mm, thickness is above 0.5mm.

- Application fields: Induction bluing, Induction quenching, Induction tempering, Induction Annealing, Induction coating, Induction plasticizing, etc.

What is wire induction heat treatment machine features?

- Automatic wire induction heat treatment machine with automatic loading and unloading function.

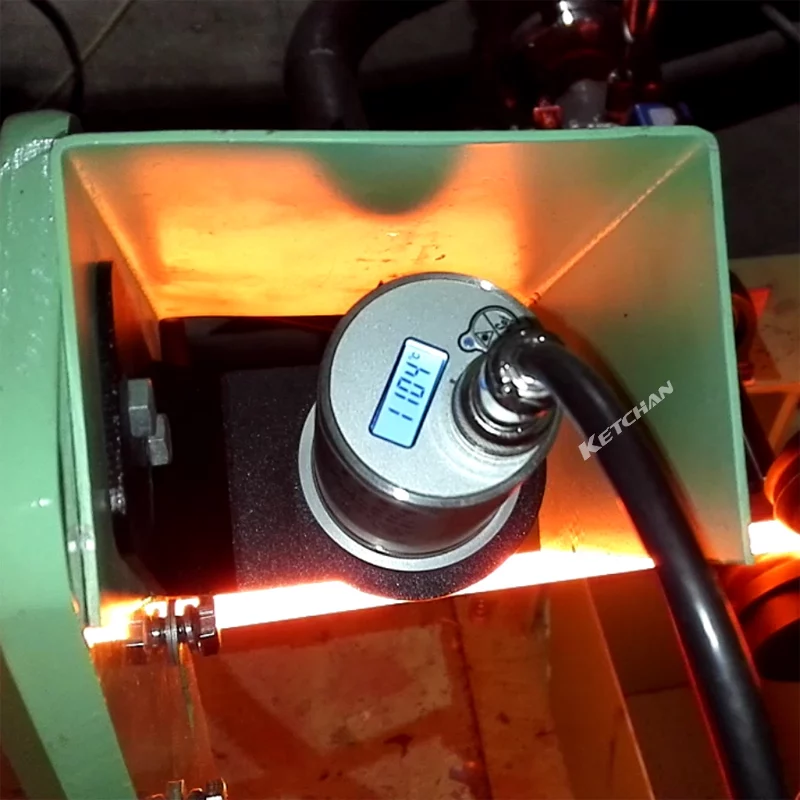

- The induction heating has a multistage heating function to ensure heating temperature uniformity. At the same time, there is a thermometer table to measure the heating temperature of bar/wire material in real time before the workpiece cooling and after tempering.

- The induction quenching power, tempering power, quenching temperature, tempering temperature, and workpiece feed speed are automatically controlled by the system, which can provide a temperature closed-loop control function.

- The heating power, power supply, current, frequency, tempering power, tempering power supply voltage, current, frequency, heating feed rate, quenching temperature, tempering temperature, and other parameters are set and recorded by the wire induction heat treatment system, and the processing parameters can be traced back accordingly.

- The high-strength welded bed is finished after aging treatment, and the performance is stable.

- Workpiece rotating and moving motor: frequency conversion speed regulation.

- Inductor replacement: manual water and electricity quick change.

- The induction coil adopts a variable turn pitch design, which is highly efficient and energy-saving.

- The induction power supply and heating furnace have water pressure protection, water flow protection, water temperature protection, air pressure protection, and photoelectric safety protection functions.

- Control box: control cabinet integrated control box.

- Alarm: sound/light fault alarm, the control interface displays the alarm information and records it.

- The inductor and water spray cooling interface: stainless steel/brass quick-change fittings are used.

- Electronic control mode: PLC/touch screen + PLC.

- The wire induction heat treatment machine tool control system can monitor and record various processing parameters, and has functions such as historical inquiry, online monitoring, and output printing.

- The automatic loading and unloading mechanism is adopted to realize the equipment’s automatic induction quenching and tempering operation.

Why choose Zhengzhou KETCHAN wire induction heat treamtent machine?

ZHENGZHOU KETCHAN Electronic Co.,Ltd, is one of the leading induction heat treatment system manufacturers in China. We have been in the induction heating field for more than 20 years and we have thousands of induction solutions application cases in our company database.

And this wire induction heat treatment machine, it is using Siemens PLC control center, combined with the perfect program design, to achieve full automatic production, saving manpower, and product stability.

Match with high-precision non-contact infrared temperature measurement can increase the temperature control accuracy to 0.5% to ensure stable product quality, can 24 hours continuously working.

We have updated the induction heating coil design as well, making the steel strip, and wires heating result more uniform.

We are direct manufacturer, can provide 24 hours after sales working and also support overseas technical service.