What is bogie hearth electric furnace?

Bogie hearth electric furnace is a cycle type operation furnace, the furnace does not divide the area. The structure of the trolley electric furnace: the bottom of the furnace is a movable trolley. Before heating, the trolley is loaded outside the furnace, the heating parts are placed on the special pad iron, and then the trolley is pulled into the furnace by the traction mechanism for heating. After heating, the trolley is pulled out of the furnace by the traction mechanism for unloading, and then the heated workpiece is hoisted to the forging equipment for processing.

What is bogie hearth electric furnace technical advantages?

- The trolley-type resistance furnace is a national standard energy-saving periodic operation furnace. The production adopts the structure of composite fiber folding block and fiber blanket, which is a super energy-saving structure and saves electricity by up to 30%.

- The trolley anti-collision sealing brick automatically seals the trolley and the furnace door.

- Bogie hearth electric furnace is mainly used for high chromium, high manganese steel castings, ductile iron, rolls, steel balls, 45 steel, stainless steel, and other quenching, annealing, aging, and heat treatment of various mechanical parts

- The trolley is equipped with a cast steel furnace bottom plate that is resistant to pressure and high temperature to carry workpieces. The multi-piece furnace bottom plate adopts a sub-mother button structure, which can effectively prevent the oxide scale generated after the workpiece is heated from falling onto the heating element through the gap between the furnace bottom plates and causing damage to the heating element.

- The heating element is made of high-temperature resistance alloy wire or belt and processed into strip and spiral shape, and is fixed on the furnace side, furnace door, rear wall, and the wire bricks placed on the trolley with high-aluminum nails, which is safe and simple, and easy to replace.

- The furnace door device is composed of a furnace door, a furnace door lifting mechanism, and a furnace door pressing device. Good safety performance, and long service life.

- The frame of the trolley is welded and formed by section steel, and its rigidity ensures that it will not deform under full load.

- The electrical control adopts the smart meter plus touch screen method: Recorded data, realize data recording, and printing. Perfect fault protection measures, such as solid state relay components damage, fan failure, and automatic sound and light alarm.

How to select the suitable bogie hearth electric furnace?

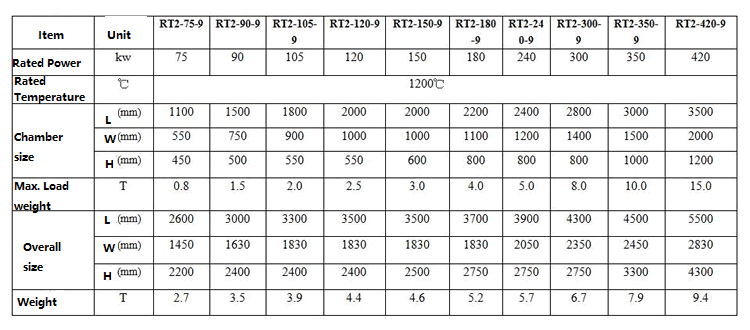

- High temperature bogie hearth furnace (0 ~ 1200℃,5 tons -10 tons)

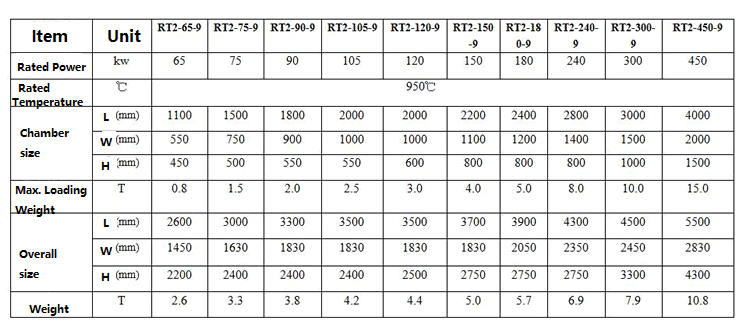

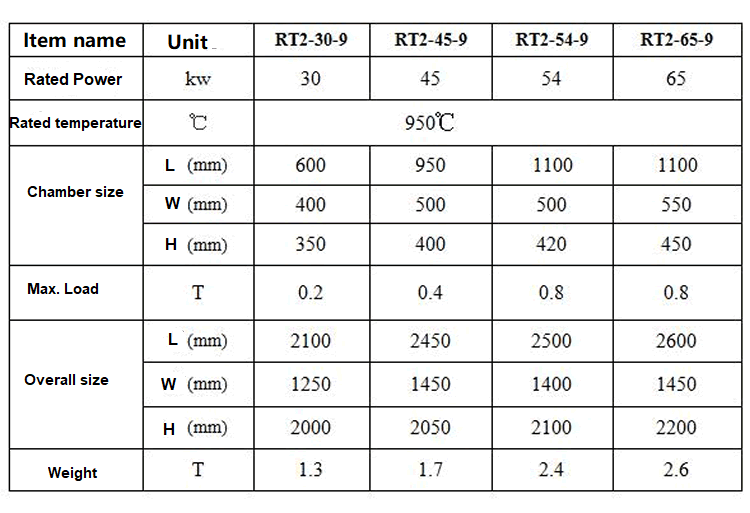

- Medium temperature bogie hearth electric furnace (0 ~ 950℃,5 tons -10tons)

- Low temperature bogie hearth electric furnace (0~750℃,5-20tons)

What is bogie hearth electric furnace applications?

- High temperature series (furnace temperature 0~1200℃) trolley type heating furnace (5 tons-100 tons) is suitable for high temperature normalizing, annealing, quenching, roll high temperature annealing, and solution treatment heating of stainless steel parts;

- Medium temperature series (furnace temperature 0~950℃) trolley type heating furnace (5 tons-100 tons) is suitable for general metal parts, and heat treatment such as normalizing, annealing, quenching, and so on is carried out in the air. Canning annealing of high-speed steel materials and bearing steel materials;

- Low temperature series (furnace temperature 0~750℃) trolley type heating furnace (5 tons-200 tons) is suitable for tempering, low temperature annealing and core drying of steel parts;

- The super-long bogie hearth electric furnace is suitable for canning, annealing, and heating of pipes, cold-drawn sections, straight rods, and coils;

- The double-door double-trolley heating furnace is suitable for the heating process of semi-continuous production of processed materials. High furnace efficiency.