What is CNC Hardening Machine Tool?

This CNC hardening machine tool is used for numerical control induction heating, and the rotation of the workpiece adopts variable frequency stepless speed regulation. The up and down movement of the workpiece is driven by a servo motor, driven by a ball screw, and guided by linear guides and linear bearings. Edit the automatic running action of the machine tool and the action of the process control through the NC program. It combines the advantages of the large diameter of the disc and the height of the shaft, which can realize the overall cooling and quenching of the disc products, wheels and ring gear products, and can also realize the scanning liquid spray quenching process of the shaft.

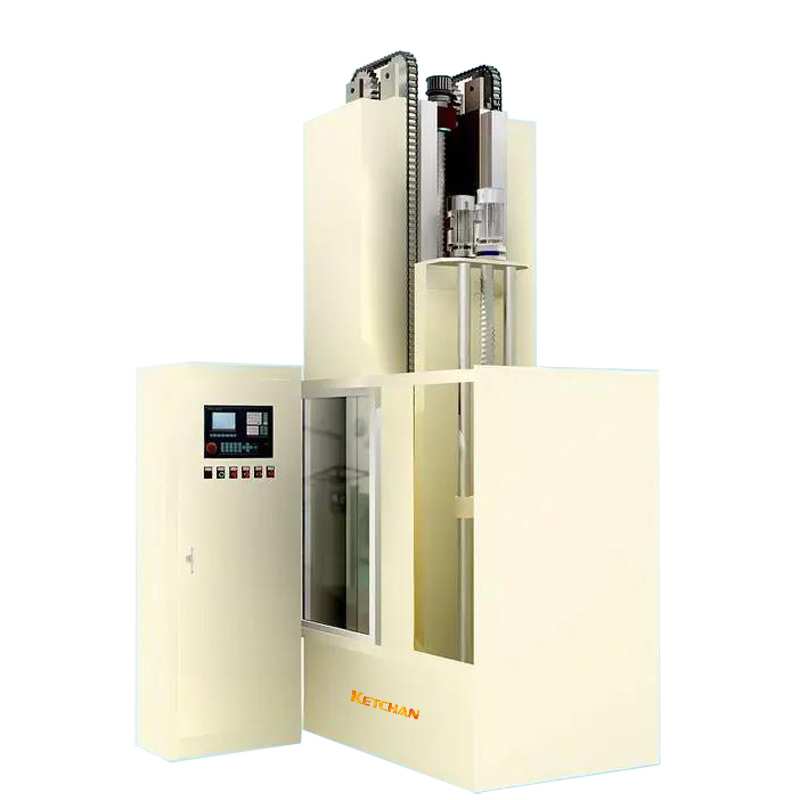

The CNC hardening machine tool is composed of a bed, control cabinet, quenching load adjustment platform, immersion spray system, overflow system, CNC lifting turntable, cooling water circulation system, transmission system, etc. The rotation system of workpiece rotation and lifting is stepless speed change by frequency conversion, and the lifting is driven by a servo motor and driven by the synchronous belt. The machine tool is easy to operate, and the shaft and disc products are universal, which is convenient to use and operate.

Performance characteristics

- It is with manual operation and fully automatic operation functions, it is suitable for the production of single and batch parts, and has the functions of continuous quenching, simultaneous quenching, subsection continuous quenching, subsection simultaneous quenching, etc.

- It is mainly used for surface quenching of various shaft parts such as half shafts, transmission shafts, camshafts, etc., and induction quenching of gears, rings and plane parts.

- It is widely used in the induction heat treatment field of tractor, automobile, construction machinery and machine tool industries. Reasonable structure, complete functions, convenient installation, and debugging.

- It has two independent stations that can work at the same time and time-sharing to speed up work efficiency. The layout of the equipment stations is convenient and compact, and it is convenient to connect to other production lines to realize linkage and automatic operation.

ZHENGZHOU KETCHAN was established in 2000. It is an early high-tech enterprise specializing in induction heating equipment and related complete sets of equipment in China. Based on IGBT induction heating power supply, the company vigorously develops induction heating electromechanical integrated products; and has successfully developed: complete sets of chain rail link equipment, sales Complete sets of shaft pin sets, driving wheels, rollers, slewing support channels, single teeth, whole teeth and other complete sets of quenching equipment, complete sets of wire heating equipment, complete sets of quenching equipment for automobile steering gear racks, complete sets of quenching equipment for the inner wall of concrete pump pipes, Complete sets of heating equipment for double-sided ribbed steel bars, complete sets of precision forging equipment for alloy copper, complete sets of equipment for on-line quenching and tempering of steel strips, complete sets of equipment for baking and eliminating solar heat concentrators and other heat treatment equipment. Products are widely used in construction machinery, machinery manufacturing, aerospace, petrochemical, metallurgy, microelectronics, light industry, electric power, scientific research and other fields.