What is induction scanning system?

CNC induction scanning system is mechatronics equipment developed by ZHENGZHOU KETCHAN. This induction scanner can meet the induction hardening process requirements of sprockets, steel sleeves, shaft parts, discs, pins, pinions, wheel bearings, and other parts. It has induction quenching functions such as continuous segmental and segmental simultaneous quenching, which is especially suitable for the production of small pieces and large batches of induction heat treatment in industries such as automobiles, motorcycles, and construction machinery, and machine tools. And this CNC quenching machine tool is mainly composed of a machine body, spindle assembly, parts rotating mechanism, parts lifting mechanism, numerical control system, transformer adjustment mechanism, cover frame, and other parts.

What is induction scanning system applications?

Zhengzhou KETCHAN induction scanning systems are widely used in the following parts of induction heat treatment fields.

- Induction heat treatment of various hardware tools and hand tools. Such as pliers, wrenches, screwdrivers, hammers, axes, etc.

- High-frequency induction hardening machine tools for various auto parts and motorcycle parts. Such as Crankshaft, connecting rod, piston pin, crank pin, sprocket, camshaft, valve, various rocker shafts; various gears in the gearbox, splines, transmission half shafts, various small shafts, various pulleys fork and other high-frequency induction quenching treatment.

- High-frequency induction hardening treatment of gears, shafts, etc. on various power tools.

- High frequency induction quenching heat treatment of various hydraulic components and pneumatic components. Such as the plunger of the plunger pump, the rotor of the rotor pump; The reversing shaft on various valves, the gear of the gear pump, etc induction quenching heat treatment.

- Induction heat treatment of all kinds of metal parts. Such as high-frequency quenching heat treatment of various gears, sprockets, various shafts, spline shafts, pins, etc.

- Quenching treatment of machine tool bed guides in the machine tool industry. Heat treatment, parts induction quenching hardening, gear quenching, stainless steel annealing, etc.

- Gears, camshafts, drive shafts, crankshafts, torsion bars, couplings, rockers, rock drills, chains, booms, clutches, brake discs, steering racks, constant velocity joints, three-column grooved shells, shock absorbers, bell housing, lever, bushing, and output shaft induction hardening tempering treatment.

What is CNC induction scanning system technical features?

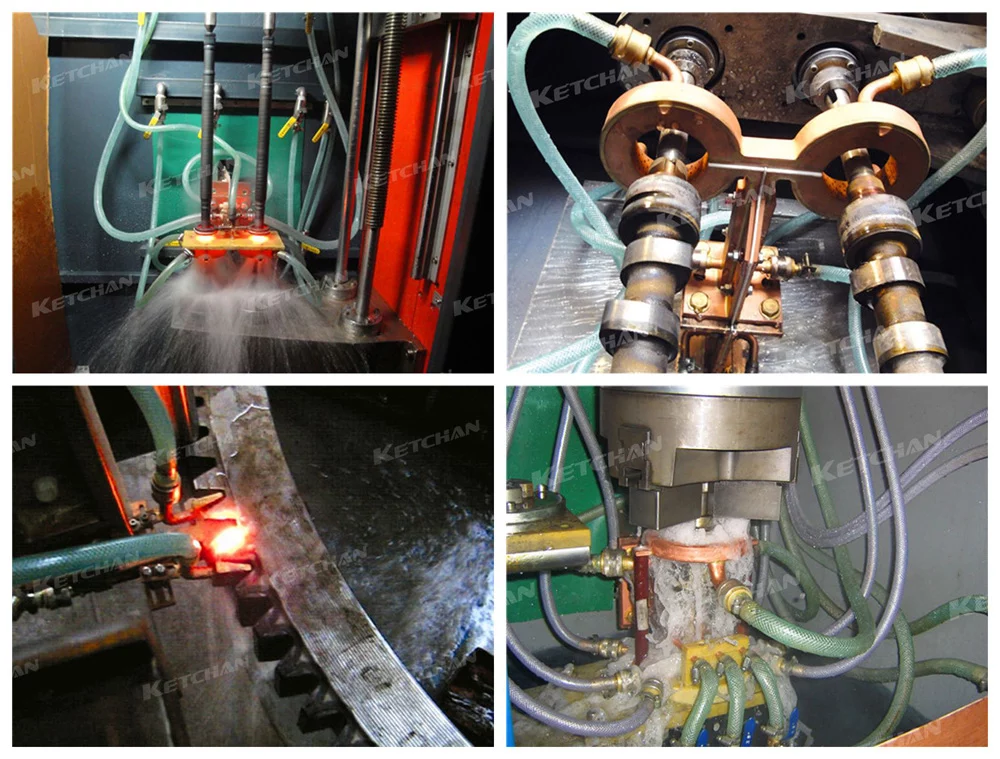

The induction scanning system mainly consists of an induction heating machine power supply, CNC induction scanner(CNC hardening machine tool),water cooling system, induction coils, and some other assistant mechanism fixtures. And the CNC induction scanner mainly consists of a machine tool body, double-layer precision worktable, upper center seat adjustment sliding mechanism, upper center assembly, table movement and transmission system, spindle rotation and transmission system, parts rotation and upper center adjustment mechanism, breeding balance, cover frame, electrical numerical control parts, etc.

- Machine tool body part: The machine tool adopts a welded bed structure, and the whole is subjected to stress relief annealing. The surface of the main exposed parts is specially treated, which has good anti-rust and anti-corrosion performance.

- Upper center adjustment mechanism: The upper center adjustment adopts electric adjustment, which can realize the clamping of different workpiece lengths.

- Worktable system: The stepper motor is used to drive the ball screw through the speed change mechanism to realize the lifting movement of the upper worktable. The moving speed is steplessly adjustable, the transmission is light, the guiding precision is high, and the positioning is accurate.

- Spindle rotation system: the asynchronous motor drives the spindle to rotate through the speed change mechanism and the transmission shaft. The frequency conversion speed regulation is adopted to realize the stepless regulation of the parts’ speed.

- Cover frame: The cover frame is made of a thick steel plate. The upper part of the cover frame is provided with a glass window and a sliding door, which not only prevents the cooling water from splashing out but also facilitates loading and unloading parts and monitoring the whole induction quenching process.

- Electrical control part: The electrical control part is composed of the numerical control system, frequency conversion governor, intermediate relay, etc.

- Our biggest advantage is that we can customize different induction scanning systems according to different application cases.

How to maintain and operate induction scanning system ?

The daily maintenance and operation of the CNC induction scanning system should pay attention to these three aspects, CNC system maintenance, mechanical system maintenance, and machine tool body structure maintenance.

- For the control system maintenance, it is necessary to regularly check if all the terminals and contacts have any looseness and poor contacts.

- Mechanical system maintenance should so regularly check the drive system shaft bearings, and ball screw, and do regular lubricating oil.

- The machine tool bed is regularly rust-proof.

- Any operation or maintenance problems, please consult our company CNC engineers.