What’s high frequency induction heater?

High frequency induction heater’s power supply, can not only heat the workpiece as a whole, but also targeted heating of parts of the workpiece; It can realize the deep diathermy of the workpiece, and can also focus on the surface heating, not only can direct heat the metal materials, but also indirect heat the non-metallic materials. Therefore, induction heating technology will be more and more widely used in all different fields of life.

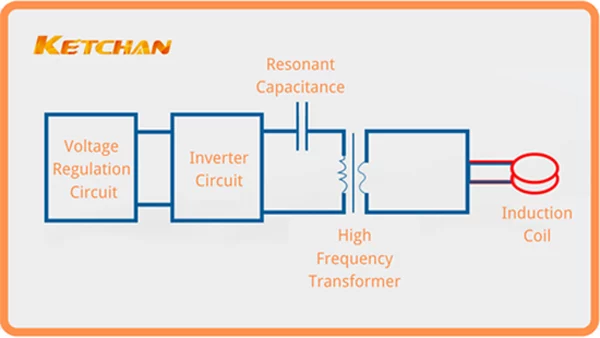

The high frequency induction heater device consists of two parts, one is the AC power supply which provides energy, also called frequency conversion power supply, and the other part is the induction coil which completes the electromagnetic induction energy conversion called induction heating furnace.

The working principle of High Frequency Induction Heater

Why use high frequency induction heater?

- High frequency induction heater adopts Siemens IGBT power tube and unique inverter technology.

- The heating and warm insulation process power and heating time can be adjusted to improve the heating quality and repeatability and simplify the operation of workers.

- Simple installation, connected to a three-phase 380V power supply, water inlet, and water outlet, can be completed in minutes.

- Small footprint, simple operation.

- Especially safe, the output voltage is lower than 36V, avoiding the danger of high voltage electric shock.

- The heating efficiency is more than 90%, saving 70% more electricity than vacuum tube high frequency machine. It can be used continuously for 24 hours.

- The induction coil can be freely disassembled, and is easy to replace. Ultra-fast heating speed greatly reduces the workpiece oxidation deformation.

- 100% load duration, can be continuously 24 hours under maximum power heating conditions.

- With constant power and constant current control function, maximum efficiency, and fast heating, optimize the metal workpiece heating process.

- Super fast heating speed: if 1kg platinum is heated for 50 seconds, it can melt.

- It can be equipped with a special output interface to facilitate joint control with external related equipment and realize production line automatic operation.

How to select a suitable high frequency induction heater?

About how to choose and select the high frequency induction heater? Mainly from the following aspects:

- Shape and dimensions of the workpiece being heated: Large workpiece, bar material, solid material, should be selected relative power, low-frequency induction heating equipment; If the workpiece is small, pipe, plate, gear, etc., the induction heating equipment with low relative power and high frequency induction heaters should be selected.

- Depth and area to be heated: Deep heating depth, large area, overall heating, should choose large power, low frequency induction heating equipment; Shallow heating depth, small area, local heating, selection of relatively small power high frequency induction heating equipment.

- The required heating speed, faster heating speed, should choose relatively large power, relatively high frequency induction heating equipment.

- The continuous working time of the equipment is long, and the induction heating equipment with slightly larger power is relatively selected.

- Distance between the induction coil and the induction heater: Long connection, even use a water-cooled cable connection, should choose relatively large power induction heating equipment.

- Process requirements: – Generally speaking, for induction quenching, welding, and other processes, can choose small power high frequency induction heaters; for Induction annealing, tempering, and other processes, choose bigger power lower frequency induction heaters; Red blanking, heat calcination, smelting, etc., need the process with good diathermy effect, so should choose bigger power, lower frequency induction heaters.

Workpiece material: high melting point metal material choose bigger power induction heater, low melting point metal material should choose smaller power induction heater. Low resistivity should choose a big power induction heater. High resistivity should choose a smaller power induction heater.

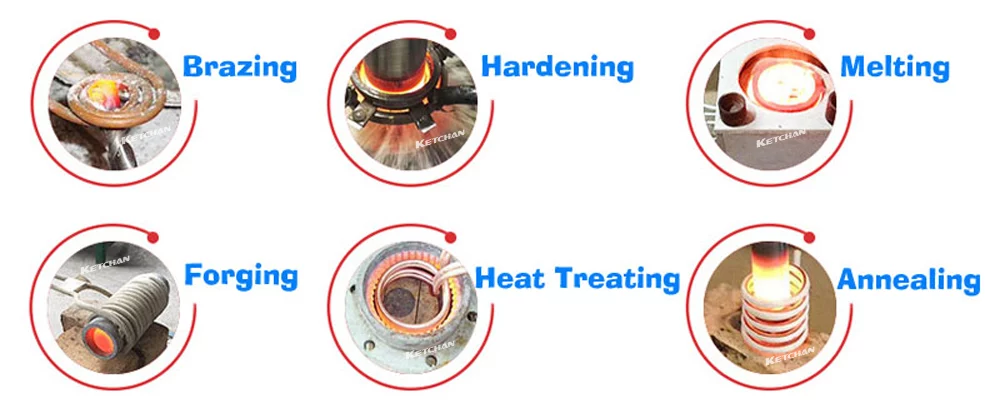

High Frequency Induction Heater applications

How to operate high frequency induction heater?

- Water supply: Start the water pump and observe whether the water flow at the outlet is normal.

- Power: first turn on the switch, then switch on the air switch behind the machine, and then open the power switch on the control board.

- Setting: Select the operation mode (automatic, semi-automatic, manual, and foot control) as required, and set the heating time, heat preservation time, and cooling time for automatic and semi-automatic control (each time cannot be set to 0, otherwise the normal automatic cycle cannot be achieved). Manual or foot control should be used for the first time and before proficiency.

- Start Each time before starting the high frequency induction heater, the heating power potentiometer should be adjusted to the minimum as far as possible. After starting, the temperature should be adjusted to the required power slowly. Press the start button to start the machine. At this time, the heating indicator on the panel lights up, and there will be a prompt sound for normal work and synchronous flashing of the working lamp.

- Observation and temperature measurement: in the heating process mainly by visual method empirically determine when to stop heating. For inexperienced operators, a thermostat can be used to check the workpiece temperature.

- Stop: Press the stop button to stop heating when the temperature reaches the requirement. Start again after replacing the workpiece.

- Turn off: the high frequency induction heater can work continuously for 24 hours, the power switch should be turned off when not in use, and the switch or air switch after the machine should be closed when not in use for a long time. Power off should be cut off after the water, for the heat inside the machine and the heat of the induction coil. Note: the machine should not work without load as far as possible, and not run without load for a long time, otherwise, the performance and stability of the machine will be affected.