Mini induction heater technical features

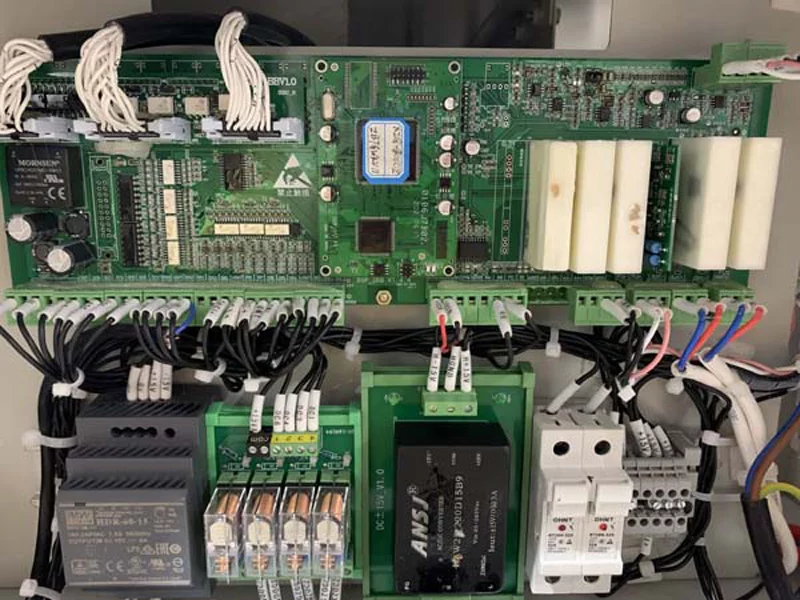

- DSP digital control

Compare to the traditional analog mini induction heater, digital mini induction heater can work more stable under the different working environments. IGBT can work normally under the best soft switch condition. Avoid the IGBT aging and broken problems, reduce the machine maintenance costs very much.

- Ultrahigh precision control

Our mini induction heater adopts high precision, frequency converting technology. All of the control processes, data processing data, parameters calculations are in the smart chip, control precision can reach NS level. Combined with the loading matching technology to make sure all the machines can work in the best power factor ranges.

- Intelligent protection

All of the induction heaters have perfect self-protection functions and rich alarm functions, like over-current, over hot, over-voltage, lack of phase, over frequency, IGBT problem alarms can help the users find the machine faulty quickly.

- Seal protection

All of our mini induction heaters machine box is customized to have well sealing, to make sure no dust comes into the machine box, and make sure all the induction heater components are working in a very clean environment.

3. Our Services

- Pre-sales: You can please let me clear about your heating parts details, including size, pictures, and drawings and technical requests will be appreciated so that we can know which of our mini induction heater models is suitable for your applications.

- In-sales: The complete mini induction heater will be installed in our factory and then adjust the induction heating process to make sure meet the users’ applications well and then do the plywood cases for the package.

- After-sales: We will first train the users on how to use the induction heaters and how to choose suitable induction heating coils. Regularly we will track to see the machine’s working conditions and will fast solve the machine working problems to ensure the machines can serve our users well.

- We support to customization of different mini induction heaters according to the different applications of your choice. And our 24 hours service hotline is:+86-15237153056.

How to select a suitable solid state induction heating machine?

Solid state induction heating machines, according to different output frequency levels can be divided into medium frequency, high frequency, and ultrahigh frequency induction heating machines. Also different induction heating process requests also need different frequency ranges. If choosing the wrong frequency level can not meet the induction heating requests, and cause the failed induction heat treating result.

- Induction hot forging: the bigger the workpiece diameter, the lower frequency should be.

- Induction heat treating: the lower the hardening depth, the high the frequency level should be. The bigger the hardening depth, the lower should frequency should be chosen.

- Induction brazing: The larger the brazing area, the lower frequency should be.

- Induction melting: We choose the suitable induction melting furnace as per the production efficiency, smaller volume can choose high frequency induction machine, and bigger volume can choose medium frequency induction machines.