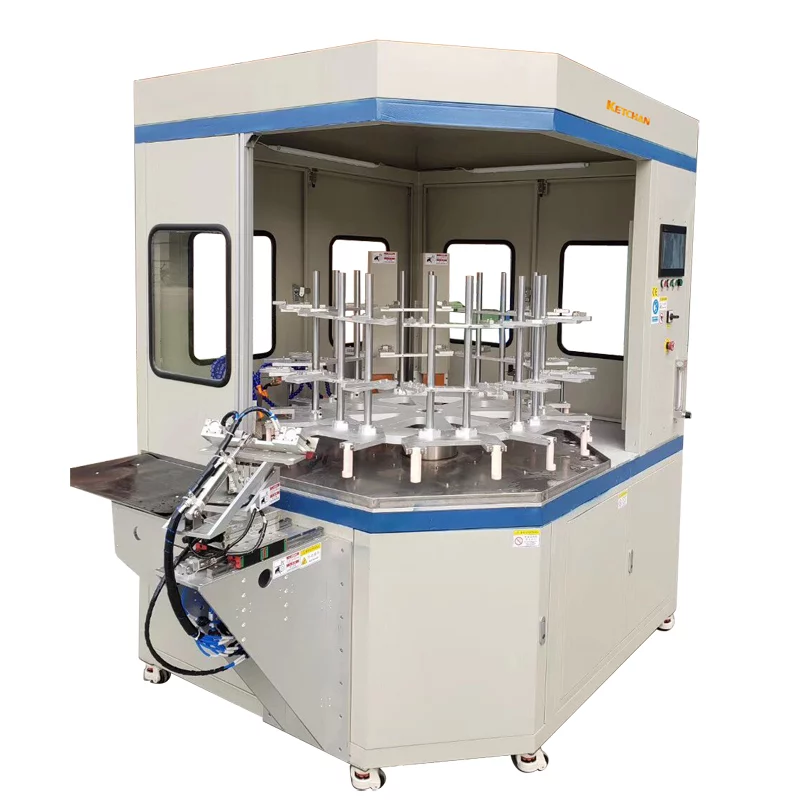

What is turntable induction brazing machine?

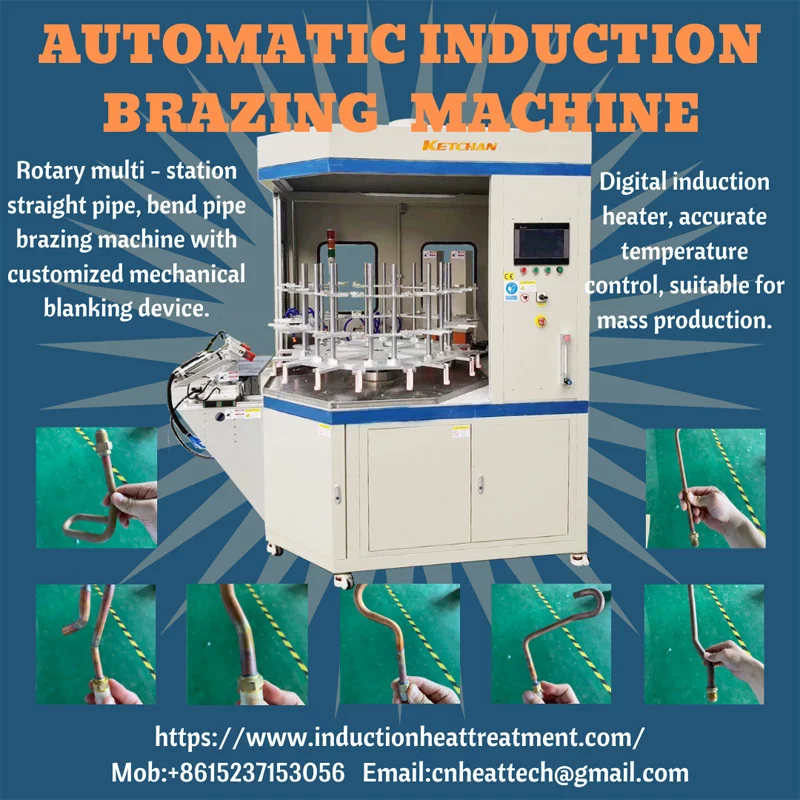

KETCHAN’s automated turntable induction brazing machine is a high efficiency induction brazing system that is specially researched for the HVAC/R accessories manufacturing industries. It has high brazing efficiency, good melting depth, mass production, easy operation, and green working environment features. Now it is a star induction machine in the induction brazing field, also we are keeping updates while using it in our user’s factories. Now it has standardized and mass production. This turntable induction brazing machine is mainly used for the AC pipelines induction brazing, automobile pipelines, and bathroom fittings induction brazing solutions.

What is turntable induction brazing machine application?

This turntable induction brazing machine is mainly used for air-conditioning refrigeration valve parts, air-conditioning pipe parts, high-end sanitary ware, lighting accessories, hardware tools induction brazing process, etc.

How to Select the suitable turntable induction brazing machine?

Intelligent Turntable Induction Brazing System Technical Date

| Product Model | KQZT-120 | Working Stations Quantity | 8 Groups 16 Stations |

|---|---|---|---|

| Brazing/Welding Beat | (8-15S) /2Pics | Operator Request | 1 person |

| High Frequency Induction Heating Machine Model | Full Digital KQ-40D | Induction Heating Machine Quantity | 2 Sets |

| Load Material Form | Manual feeding automatic brazing/welding | Unloading Material Form | Manual or Automatic blanking |

| Display Screen Size | 10-inch touch screen | High Frequency Induction Brazing Machine Model | DSP full digital Control |

| Segmented Heating | 5 sections | Store Products Quantity | 8 kinds |

| Max. Power | 50KW | Max. Input Current | 80A |

| Rated Power | 30KW | Rated Current | 45A |

| Motor Type | Servo motor | Maximum Lift Stroke | 200cm |

| Inductor Lifting Speed | 100mm/s | Elevation Accuracy | 0.1mm |

| Tooling Base Type | Special ceramics | Tooling Base Type Quantity | 16 Pics |

| Nitrogen Protection Function | Equiped | Air Cooled Function | Equipped with air cooling |

| Water Cooling Function | Independent water cooling system | Lighting Function | Stations, switch box lighting |

| Working Table Material | Aluminum alloy | Water Tank Type | 304 stainless steel |

| Equipment Overall Size | 1450*1600*2360mm | Equipment Weight | 400Kg |

| Industrial Chiller | 3P | Water Quality Requirement | Unfouled purified water |

| Cooling Water Flow | 4L/Min | Cooling Water Pressure | 4-8 Bar |

| Cooling Water Max. Inlet Temperature | 35℃ | Cooling Water PH | 7.0-9.0 |

What are turntable induction brazing machine features?

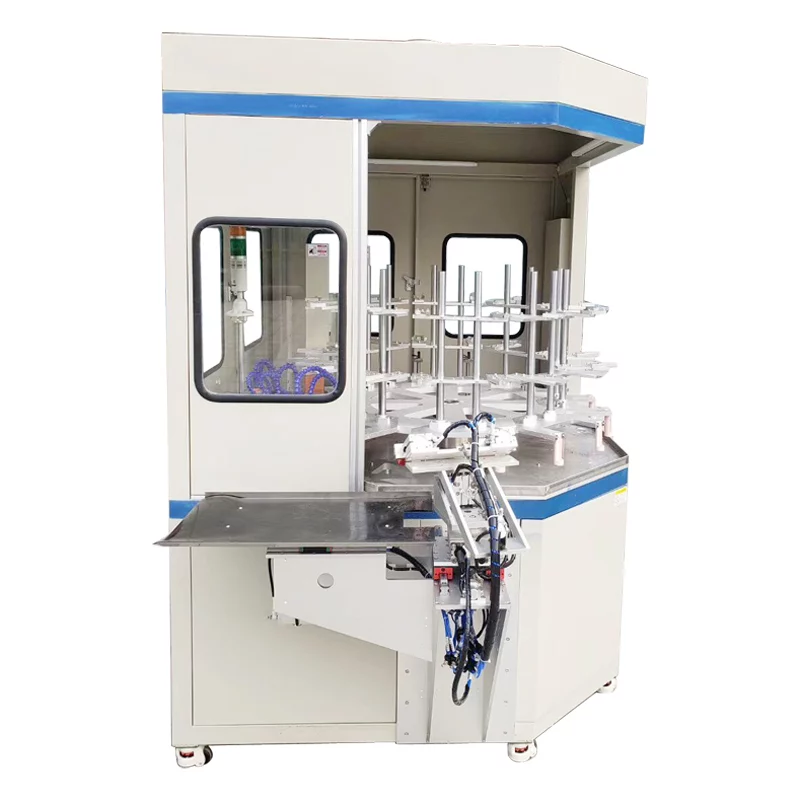

- Material Loading: ZHENGZHOU KETCHAN turntable induction brazing machine normal with manually load material, equip with one operator. Operators only need to place the product in the appropriate position to carry out automatic welding. There is no need to manually adjust the equipment parameters. The product parameters are well set, the corresponding product parameters can be called out when working.

- Automatic Brazing Welding: After the turntable is set to the automatic welding mode, the operator will place the to-be welded products on the corresponding tooling, and the turntable will automatically rotate to the next testing station. Automatic welding, air cooling, water cooling and material receiving functions will be carried out when products are detected at the testing station. If no welding product is detected, it will automatically rotate but no longer run the next steps.

- Unloading Material: Turntable equipment unloading material is divided into two kinds: One is automatic unloading, you can choose robot unloading, And also choose the automatic device. Self-unloading material is suitable for assembly line operation. Using robots to unload material can be flexible for docking the next station. The other is the artificial material collection, In the case of simple welding products, loading and unloading can be performed by the same operator.

- High Yield: When you need a large amount of welding production, Ketchan turntable induction brazing equipment is your best choice. Not only can meet your production needs, but also can save labor costs, convenient for management. No matter what products you do we can design a full range of welding programs for your applications.

- High Quality: Turntable induction brazing equipment has the incomparable deep penetration effect of automatic flame brazing and manual brazing. Induction brazing of pipe joints can reach the deepest penetration. Also the induction brazing time is short the surface joint is less oxidized. The grain size of the copper tube is also better than that of flame welding.

- Energy-saving, good environment, and safety: Turntable induction brazing machine has more advantages than flame automatic brazing in energy saving and convenience. Turntable induction brazing only starts high frequency machine when brazing, the rest time was in standby mode. And the turntable flame brazing, in the whole process, whether welding product or not, the flame has been always in a burning state. A lot of gas is wasted low energy conversion rate. For the environmental protection induction brazing basically does not produce pollution gas, and also does not need a complex gas pipeline, to protect the worker’s health and safety well.

- Good Stability and High Reliability: Zhengzhou KETCHAN turntable induction brazing equipment, equipped with two digital induction heating power supply, to ensure the welding reliability. Equipped with two sets of servo motors to achieve mobile heating.In addition, the equipment is equipped with air cooling, water cooling, nitrogen and other protection functions. Each part of the equipment has been verified many times in the actual production to ensure the equipment high reliability and high stability.