What are the advantages of induction surface hardening?

Induction surface hardening: the process of quenching only the surface of the workpiece.

Purpose: The martensite structure is obtained within a certain depth range on the surface of the workpiece, and the core still maintains the structure state of quenching and tempering or normalizing before surface quenching to make the surface layer of the workpiece hard and wear-resistant, and the core retains enough plasticity and toughness.

Parameters: Depth of hardened layer and hardness gradient. When determining the depth of the hardened layer and the hardness gradient, the surface hardened layer should be matched with the load stress distribution of the workpiece.

What is induction surface hardening?

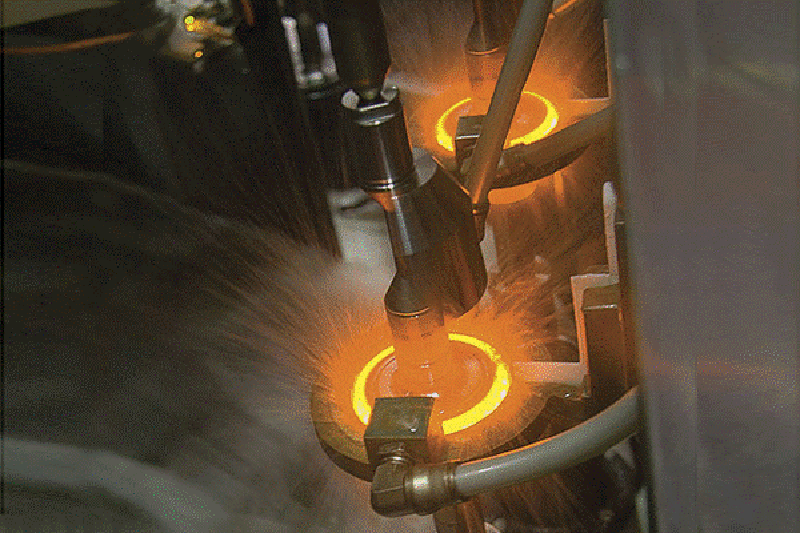

Induction hardening process in which the surface of the workpiece is heated and rapidly cooled by the thermal effect generated by the induction current passing through the workpiece.

- The basic principle of induction heating

Physical phenomena such as electromagnetic induction, eddy current heating, and hysteresis heating, as well as the distribution characteristics of alternating electricity in conductors, are utilized.

When an alternating current flows through the inductor, an alternating magnetic field of the same frequency will be generated around it. Under the action of the alternating magnetic field, an induced electromotive force will be generated in the workpiece, thereby generating an induced current with the same frequency and opposite direction as the inductor, that is, eddy current. Eddy current is converted into heat energy due to the resistance of the workpiece itself, thereby heating the workpiece, also known as eddy current heating.

- Induction heating machine classification and applications

According to the output, the current frequency can be divided into high frequency, medium frequency, power frequency, and ultrahigh frequency induction heating machines.

Induction heating machine | Frequency range | Power | Application ranges |

Power frequency induction heating machine | 0.05KHZ | 100-2000 | It is suitable for bigger roller and bigger diameter shafts induction surface hardening process. |

Medium frequency induction heating machine | 10KHZ | 15-1000 | 1. bigger module gears, camshaft, crankshaft surface induction hardening. 2. small and middle shaft and bearing sleeves induction hardening. |

High frequency induction heating machine | 30-60KHZ | 5-500 | 1. small or middle module gears, spindle surface induction hardening 2. crankshaft, camshaft hardening. |

Ultrahigh frequency induction heating machine | ≥200KHZ |

| 1. Smaller module gears surface induction hardening. 2. Smaller shaft surface induction hardening. |

What are the metal performance after induction surface hardening?

- Surface hardness: The surface hardness of workpieces subjected to rapid heating and quenching is often 2 to 5 percentage points higher than that of ordinary quenching.

- Wear resistance: The wear resistance of the workpiece after rapid heating surface quenching is better than that of ordinary quenching.

- Fatigue Strength: Using the correct case hardening process can significantly improve the fatigue resistance of the part.

- Residual stress distribution: The magnitude and distribution of residual stress after surface quenching are related to various factors such as steel grade, part size, depth of hardened layer, heating and cooling, etc.

What is induction surface hardening process?

The induction hardening process mainly includes the selection and determination of frequency and specific power, the selection and determination of heating method and heating process parameters, the selection and determination of cooling medium and cooling method, etc.

Determination of frequency and specific power:

The current frequency should be selected reasonably according to the requirements of the depth of the hardened layer. When selecting the current frequency according to the depth of the hardened layer, it can be found in the heat treatment manual.

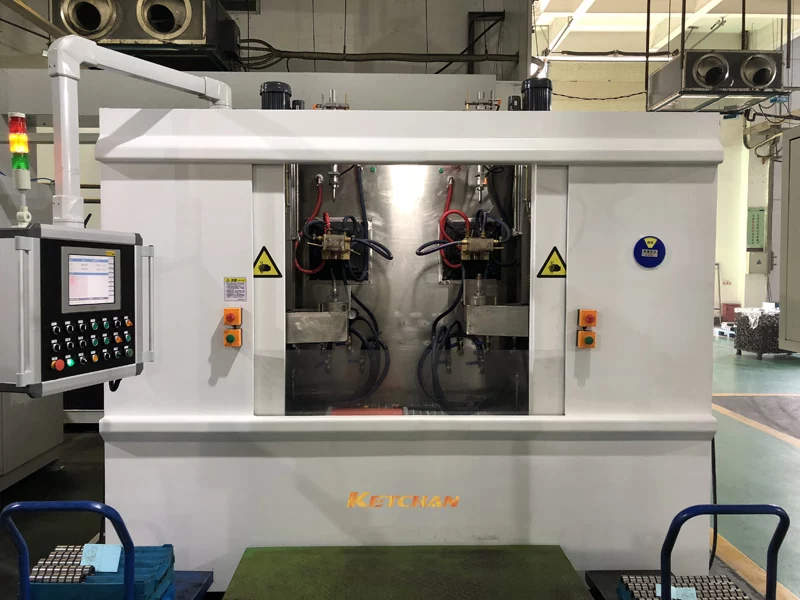

Relate Products

-

Induction Heat Treatment system

Gear Hardening Machine

-

Induction Heat Treatment system

Surface Hardening Machine

-

Induction Heat Treatment system

Shaft Induction Hardening Machine

-

Induction Heat Treatment system

Crankshaft Induction Hardening Machine

-

CNC Hardening System

Shaft CNC Hardening Machine Tool

-

CNC Hardening System

Induction Quenching System