With the high and strict requirements for efficiency and environmental protection in the industry, the country’s requirements for standardized production in factories are becoming more and more stringent, so the equipment used in production to achieve standardized production must also conform to industrial-grade equipment.

At present, the medium frequency induction melting equipment on the market is mostly modified from civilian workpieces, and the heating is unstable and there is no safety guarantee.

The medium frequency induction melting furnace equipment developed by Zhengzhou Ketchan especially for industrial production has stable heating, and the unique leakage protection device not only improves the work efficiency of the factory, but also guarantees safety issues.

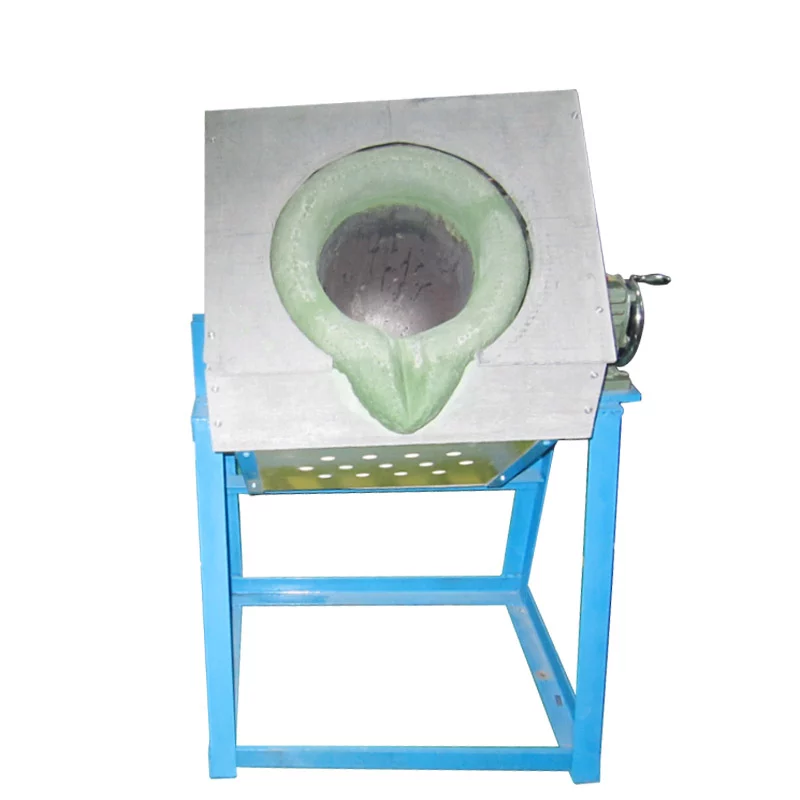

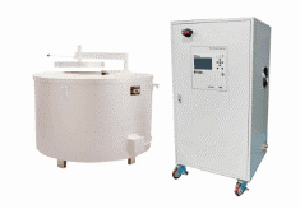

The intermediate frequency melting furnace of our company consists of two parts, an induction heating power source, and a crucible.

Features of medium frequency induction melting furnace

- The electromagnetic induction melting furnace adopts imported components and a full digital control circuit. The equipment has rich communication interfaces, which can realize remote control and simple operation.

- The crucible furnace adopts PID closed-loop control, precise temperature control, small size, high efficiency, low energy consumption, and fast melting and heating.

- The most important point is that our company’s smelting furnace adopts the working principle of induction heating. Through non-contact heating of metal, the heat loss is small, and the thermal efficiency is as high as about 70%. The warm-up time is shortened by 2/3.

- Since the heating process almost only generates heat inside the workpiece, the furnace body itself does not generate high temperature, which prolongs the service life of the melting furnace and reduces maintenance costs.

With the continuous development of the industry, we can see that the high thermal efficiency and low cost of the intermediate frequency melting furnace have gradually exceeded the value brought by the use of traditional heating equipment, so it is also the general trend to choose the intermediate frequency induction melting furnace.

What is high frequency induction hardening machine?

A medium frequency induction melting furnace is used for smelting steel, immortal steel, brass, copper, aluminum, aluminum alloy, gold, silver, and other metal materials, and the smelting capacity ranges from 3kg to 500kg.

Classification of induction melting furnaces

There are three types of smelting furnaces: pouring smelting furnaces, top-out smelting furnaces, and stationary smelting furnaces. Dumping furnace: can be divided into mechanical dumping furnace, electric dumping furnace, and hydraulic type

Some of the induction melting furnace applications cases display

Relate Products

-

MF Induction Heating System

Medium Frequency Induction Melting Furnace

-

Induction Melting System

IGBT Induction Melting Furnace

-

Induction Melting System

Metal Induction Melting Furnace

-

Induction Melting System

Induction Melting Furnace

-

Induction Melting System

Silver Melting Furnace

-

Induction Melting System

Gold Melting Furnace