With the continuous development of the domestic industrial situation, the market demand of the machine tool industry has become larger and larger in recent years, and the quality requirements of users on the machine tools are also getting higher and higher. One of the keys to the quality and life of a machine tool depends on the accuracy of the machine tool guide surface and the quenching process requirements. If the guide rail surface of this machine tool is not quenched, then the accuracy and life of this machine tool are not guaranteed. So this article will show you how to Induction Harden Machine Guide Rails With Induction Heating.

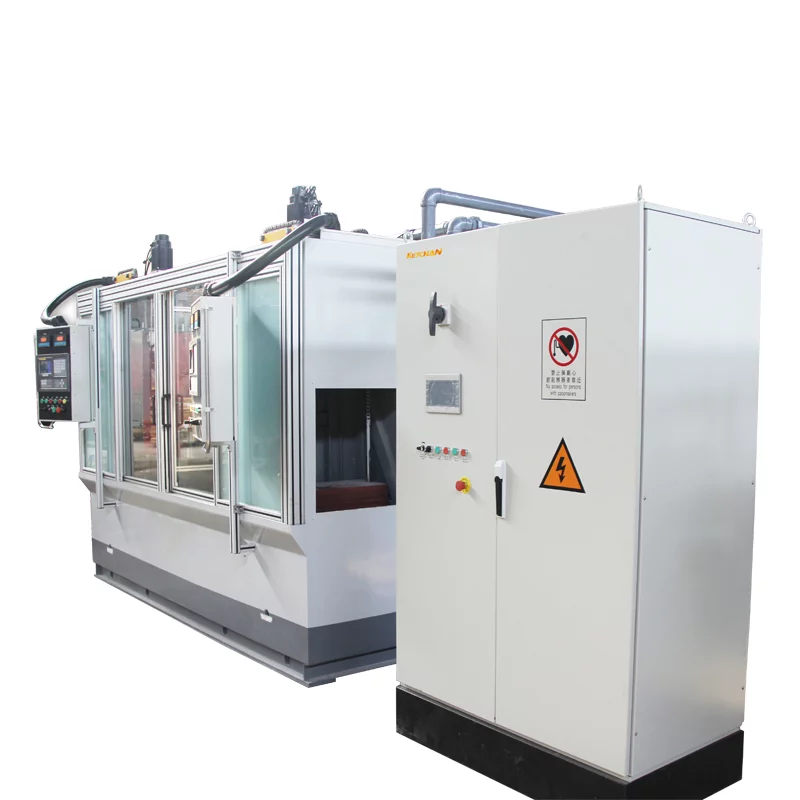

Machine guide rail hardening system strucuture:

This machine guide rail induction hardening system is a high-frequency quenching process for the guide rail, equipped with a complete set of automatic quenching equipment, including high-frequency induction heating part, cooling part, and mechanical parts.

The induction hardening system uses two high-frequency heating power sources, which are fixedly installed on both sides of the guide rail, and the profiling inductor is used to quench the sharp corners of the guide rail to achieve quenching hardness and layer depth;

The cooling part mainly cools the high-frequency power supply, the induction coil, and the workpiece. The mechanical part mainly drives the guide rail to move through the roller, so that the guide rail passes through the induction coil at a constant speed, and at the same time controls the cooling and movement of the workpiece. The workpiece is manually loaded, and the finished product needs to be manually unloaded.

Machine Guide Rail Hardening Process:

Manually loading the workpiece→positioning→heating→cooling→manually unloading the workpiece.

Technical Advantages of Zhengzhou Ketchan

- IGBT transistors are used as inverter devices, and their power consumption is only one-fifth of the high-frequency equipment of electronic tubes;

- Adopt an all-digital embedded digital control system, higher heating accuracy;

- No radiation to the human body, safe and environmentally friendly;

- Small size, lightweight, easy to move;

- Low voltage output, safe and reliable.

- Simple operation and convenient maintenance;

- With overvoltage, overcurrent, overheating, lack of phase, lack of water, abnormal load, out of control, and other sound and light alarm protection functions;

- With manual mode, automatic mode, and temperature control mode, various modes can be switched freely;

- The heating frequency, current, and time are displayed in real-time, and the time current curve is drawn;

- Constant power and constant current control.

Tags:for Sale, guide rail induction hardening equipment, guide rail induction quenching, guide rails induction hardening process, hardening of machine tools, induction hardening, induction hardening machine, induction heater, induction heating, induction heating machine, induction quenching machine, KETCHAN, KETCHAN Electronic, linear guide induction hardening solution, Linear guide quenching equipment, machine guideway induction hardening, machine rail surface hardening, machine tool guide rail induction hardening, machine tool guide rail induction quenching, manufacturer, Manufacturers, price, rail surface induction heat treating, supplier, Suppliers, Zhengzhou KETCHAN, Zhengzhou KETCHAN Electronic

Relate Products

-

CNC Hardening System

CNC Induction Hardening Machine

-

Induction Heat Treatment system

Induction Heat Treating Equipment

-

Induction Heat Treatment system

Induction Hardening Machine

-

HF Induction Heating System

High Frequency Induction Quenching Machine

-

HF Induction Heating System

Industrial Induction Heating Machine

-

UHF Induction Heating System

Ultra high Frequency Hardening Machine