KETCHAN Induction provides the most intelligent, energy-saving digital induction heating machines and solid-state induction heating power supply with stable quality.

- The power range of our medium frequency 500Hz-20KHz machines is from 15kw to 3000kw.

- The power range of the high-frequency 10KHz-80KHz machine is 5kw to 1200kw.

- The power range of the UHF 10KHz-2MHz machine is 10kw to 800kw.

Our induction heating machines are usually used for casting, forging, quenching of auto parts, thermal assembly and disassembly of motors, brazing in the refrigeration and HVAC industry, heating of small parts in the medical industry, and the emerging electric vehicle industry and 5G industry.

In communicating with many customers, we found that many customers will ask our experts to recommend suitable machines for customers based on their experience, and we are very happy to provide such services. But for complex process requirements, we are more willing to use the results of experiments, including photos, videos, anatomical parts or hardness reports and other materials to facilitate our cooperation.

Industrial Induction Heating Machines for Sale

High Frequency Heating Machine

1 20 years of Induction heating machines experience

2 Siemens high frequency heating machine

3 Fast heating speed wide application ranges

4 Easy to

Industrial Induction Heating Machine

1 Metal industrial induction heating machine

2 Automatic frequency tracking

3 Siemens IGBT as main inverter components

4 High frequency level fast heating speed

Medium Frequency Induction Heating Equipment

1 Medium frequency induction heating equipment manufacturer

2 Full solid IGBT induction heating equipment

3 Easy to install and no high voltage

4 Wide

Ultra high Frequency Induction Heating Equipment

1 IGBT ultra high frequency induction heating equipment

2 With Infineon IGBT MOSFET as inverted components

3 Wide application range fast heating speed

4

Air Cooled Induction Heating Machine

1 Full air cooled induction heating machine

2 With DSP control technology

3 Easy to move and install

4 Suitable for wild working environments

High Frequency Heating Machine

1. 20 years of Induction heating machines experience.

2. Siemens high frequency heating machine.

3. Fast heating speed, wide application ranges.

4. Easy to operate and green to the environment.

5. With timer and temperature controller.

6. Have CE, SGS, and ISO9001 certifications.

Industrial Induction Heating Machine

1. Metal industrial induction heating machine.

2. Automatic frequency tracking.

3. Siemens IGBT as main inverter components.

4. High frequency level, fast heating speed.

5. Perfect alarm protection function.

6. With CE, SGS, and ISO9001 certification.

Medium Frequency Induction Heating Equipment

1. Medium frequency induction heating equipment manufacturer.

2. Full solid IGBT induction heating equipment.

3. Easy to install and no high voltage.

4. Wide application range, 24 hours non-stop working.

5. PLC digital control, more intelligent.

Ultra high Frequency Induction Heating Equipment

1. IGBT ultra high frequency induction heating equipment.

2. With Infineon IGBT, MOSFET as inverted components.

3. Wide application range, fast heating speed.

4. Perfect alarm functions,professional after sales.

5. Can 24 hours non-stop working,energy-saving.

6. Has CE,SGS, ISO9001 certifications.

Air Cooled Induction Heating Machine

1. Full air cooled induction heating machine.

2. With DSP control technology.

3. Easy to move and install.

4. Suitable for wild working environments.

5. High heating efficiency, energy-saving.

Free technical advice. The experienced engineering team is ready for you!

Machine Features

Induction heating machines are devices that use electromagnetic induction to heat metal objects. They have many features and applications in various industries. Some of the features of induction heating machines are:

- They can heat metal objects quickly and uniformly, without direct contact or flame.

- They can control the temperature and heating rate precisely, using a microprocessor or a temperature probe.

- They can operate at different frequencies, depending on the size and type of the metal object.

- They can save energy and reduce pollution, compared to other heating methods.

- They can produce high-quality products, with minimal distortion, oxidation, or loss of alloying elements.

Optional Equipment

Some of the optional equipment for induction heating machines are:

- Custom induction coils: These are induction coils that are designed and fabricated according to the shape and size of the workpiece or joint that needs to be heated. Custom induction coils can improve the heating efficiency, uniformity, and quality of the induction heating process.

- Foot switch: This is a device that allows the operator to control the operation of the induction heating machine by using their foot. Foot switch can provide convenience and safety for the operator, especially when they need to use both hands to handle the workpiece or the induction coil.

- Infrared thermometer: This is a device that can measure the temperature of the workpiece or the joint without touching them. Infrared thermometer can provide real-time temperature monitoring and control of the induction heating system, and prevent overheating or underheating of the workpiece or the joint.

- Water cooling system: This is a device that can provide cooling water for the induction heating machine and the induction coil. Water cooling system can prevent overheating or damage of the induction heating machine and the induction coil, and improve the service life and performance of the induction heating system. Water cooling system can be either industrial chillers or cooling towers, depending on the environmental requirements.

Applications

Some of the applications of induction heating machines are:

- Melting, casting, forging, and welding of metals, such as iron, steel, copper, aluminum, and precious metals.

- Annealing, hardening, tempering, and quenching of metals, to improve their mechanical properties and surface quality.

- Brazing, soldering, and bonding of metals, such as pipes, wires, tubes, and fittings.

- Curing and setting of adhesives, such as in automotive, aerospace, and fiber optics industries.

- Sealing and sterilizing of containers, such as in food and pharmaceutical industries.

- Removing and loosening of bolts, rivets, bearings, and gears.

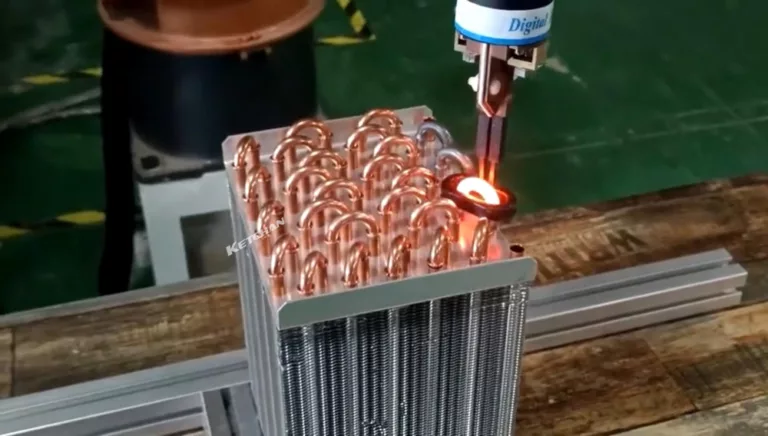

Induction Brazing (with pictures, videos, applications)

What’s Induction Brazing? Get A Quote https://www.youtube.com/watch?v=io3fURkB0WE Induction brazing is using alternating magnetic field – electromagnetic induction phenomenon, the eddy current effect in the magnetic field heats the workpiece,

Induction Melting (with pictures, videos, applications)

What’s Induction melting? Get A Quote https://www.youtube.com/watch?v=kyGyJAh667s The induction melting furnace is based on the electromagnetic induction heating principle to work, through electromagnetic induction to generate heat, the heating

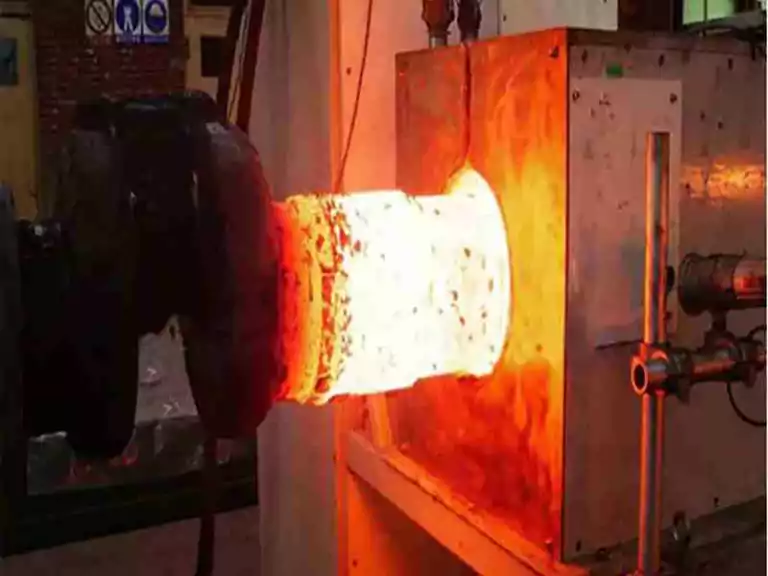

Induction Forging (with pictures, videos, applications)

What’s Induction forging? Get A Quote https://www.youtube.com/watch?v=78B3X_PQrX0 The core principle of induction forging furnace is to convert power frequency 50HZ AC to medium frequency (300HZ-20khz). The three-phase alternating current

Induction Hardening (with pictures, videos, applications)

What’s Induction Hardening? Get A Quote https://www.youtube.com/watch?v=4R0me_Blhic Induction hardening is a quenching method that uses the principle of electromagnetic induction to make the workpiece cut magnetic field lines in

Induction Annealing (with pictures, videos, applications)

What’s Induction annealing? Get A Quote Induction annealing is a part of induction heating. The purpose of induction annealing is to change the metal material’s hardness, toughness, and internal stress

Induction Tempering (with pictures, videos, applications)

What’s Induction tempering? Get A Quote For the whole induction hardening workpiece, especially the induction through heating hardening workpiece, the application of induction heating tempering is more convenient to form

Industries

Induction heating machines can be used for a variety of industries, such as:

- Metalworking: Induction heating can be used for surface hardening, annealing, tempering, stress relieving, forging, melting, brazing, and soldering of metals. Induction heating provides a fast, precise, and energy-efficient way of heating metals without contact or flame.

- Plastics: Induction heating can be used for plastic injection molding, plastic reflow and heat staking, and catheter tipping. Induction heating improves the quality and efficiency of plastic processing by reducing cycle times, energy consumption, and defects.

- Semiconductor: Induction heating can be used for heating of silicon and other semiconductor materials for crystal growing, doping, and bonding. Induction heating provides a clean, uniform, and controlled way of heating semiconductor materials without contamination or damage.

- Medical: Induction heating can be used for sterilization of medical instruments, sealing of pharmaceutical products, and bonding of medical devices. Induction heating provides a safe, reliable, and hygienic way of heating medical materials without contact or flame.

- Food: Induction heating can be used for cooking, pasteurization, sterilization, and sealing of food products. Induction heating provides a fast, efficient, and consistent way of heating food without burning or overcooking.

Induction Heating Solutions for Auto Parts

Advantages and Disadvantages of Induction Heat Treatment Auto Parts Induction heat treatment is a process that uses electromagnetic fields to heat metal parts or components without direct contact. It is

Induction Heating of Composite Materials

Induction heating is a technology that uses an alternating electromagnetic field to heat ferromagnetic and conductive materials and has been adapted to polymeric materials and composites in the past

What can Induction Heating Technology Do for the 5G Industry?

Induction heating technology can potentially provide benefits for the 5G industry in terms of manufacturing, testing, and repairing 5G components and devices. Such as: Manufacturing of 5G components and

Electric Vehicle Induction Heating & Hardening & Brazing

Electric Vehicles and Induction Heating In the past few years, people’s demand for electric vehicles has increased significantly, and electric vehicles have become a new track pursued by major

Induction Soldering Precision Solutions

What is induction soldering? Induction soldering works by using a precise electromagnetic field to heat two or more electrically conductive materials in order to join them with a filler

Induction Brazing Solutions For HVAC Industry

Composition of air conditioning accessories Air conditioning accessories include circuit control boards, wire controllers, manifolds, refrigerants, electronic expansion valves, motors, compressors, liquid mirrors, and ball valves. High-frequency induction brazing technology

FAQ

How does an induction heating works?

Induction heating is a process of heating electrically conductive materials, such as metals, by exposing them to an alternating magnetic field. The magnetic field is created by passing a high-frequency alternating current (AC) through an induction coil or an electromagnet. The magnetic field induces electric currents inside the material, called eddy currents, which generate heat due to the resistance of the material. Induction heating is a non-contact, precise, repeatable, and cost-effective heating method that can be used for various applications, such as heat treating, brazing, soldering, melting, and more.

What are the advantages of induction heating machines ?

Induction heating machines are devices that use induction heating to heat, melt, or treat various materials, such as metals, plastics, or ceramics. Induction heating machines have many advantages over other heating methods, such as:

- They are fast and efficient, as they can heat the material directly and uniformly without wasting heat to the surroundings.

- They are safe and clean, as they do not produce any noise, dust, smoke, or harmful emissions. They also do not require any direct contact with the power supply or the material, reducing the risk of electric shock, fire, or damage.

- They are precise and controllable, as they can adjust the heating temperature, time, and depth according to the specific requirements of the application. They can also heat the material selectively, locally, or globally, depending on the shape and size of the induction coil.

- They are versatile and flexible, as they can be used for various applications, such as heat treating, brazing, soldering, melting, forging, welding, annealing, tempering, and more. They can also handle different types of materials, such as ferrous and non-ferrous metals, plastics, ceramics, composites, and more.

Induction heating machines are widely used in various industries, such as automotive, aerospace, medical, energy, construction, mining, metallurgy, and more. KETCHAN Induction offers a reliable, cost-effective, and sustainable solution for heating needs.

How to choose a right cooling system for induction heating machines?

Choosing the right cooling system for induction heating machines depends on several factors, such as the size and power of the induction machine, the cooling capacity and efficiency required, the available space and utilities, the environmental conditions and regulations, the initial and operating costs, and the maintenance and reliability issues. There is no one-size-fits-all solution, but rather a trade-off between different advantages and disadvantages of each cooling system.

There are three main types of cooling systems for induction heating machines: water-to-water plate heat exchangers, air-cooled heat exchangers (dry coolers), and open evaporative towers. Each of these systems has its own pros and cons, as summarized below:

- Water-to-water plate heat exchangers: These systems use a secondary water loop to transfer heat from the induction machine to a chiller or a cooling tower. They are suitable for smaller induction machines that require precise temperature control and low water consumption. They are also easy to install and operate, but they may have higher initial and operating costs than other systems.

- Air-cooled heat exchangers (dry coolers): These systems use fans to blow ambient air over finned tubes that carry the water from the induction machine. They are suitable for larger induction machines that can operate at higher temperatures and do not require precise temperature control. They are also energy-efficient, environmentally friendly, and low-maintenance, but they may have lower cooling capacity and efficiency than other systems, especially in hot climates.

- Open evaporative towers: These systems use the evaporation of water to cool the water from the induction machine. They are suitable for multiple induction machines that have high cooling capacity and efficiency requirements. They are also cost-effective and reliable, but they may have high water consumption and treatment needs, as well as potential noise and environmental issues.

Feel free to consult KETCHAN induction experts for professional advice.