Handheld portable induction heating equipment adopts DSP digital control system and coaxial transformer of small size and lightweight. It is a highly integrated power supply specially designed for supporting industrial robots, automation equipment, and manual hand-held heating. It is widely used in brazing, Curing, thermal expansion, quenching, straightening, etc.

Advantages of Portable induction brazing machine:

- DSP performs digital precise control, realizes multi-stage heating curve programming, the heating time can be accurate to 0.1 seconds, realizes various operating parameters display, rich interfaces, and can store equipment operating parameters.

- Increased productivity: Fast, easy-to-use, precise, and repeatable heat transfer increases productivity.

- Improve the working environment: no flame, no gas, and no heat radiation, so that the operator has a more comfortable and environmentally friendly working environment. This increases productivity while protecting the natural environment.

- Let you get more done: Portable mobility and application versatility allow you to accomplish a wide variety of heating tasks.

- Reduce costs: Efficient and precise heating processes mean you get things done right the first time. Minimize scrap, rework and energy consumption.

The above is the relevant introduction to the handheld portable induction heating equipment. The operation of this product is very simple. You can learn it in a few minutes by following the steps of the manual. It can heat any metal and has a wide range of applications. For information on heating equipment, please pay attention to our website, warmly welcome you to visit and guide!

Applications of handheld portable induction brazing machine:

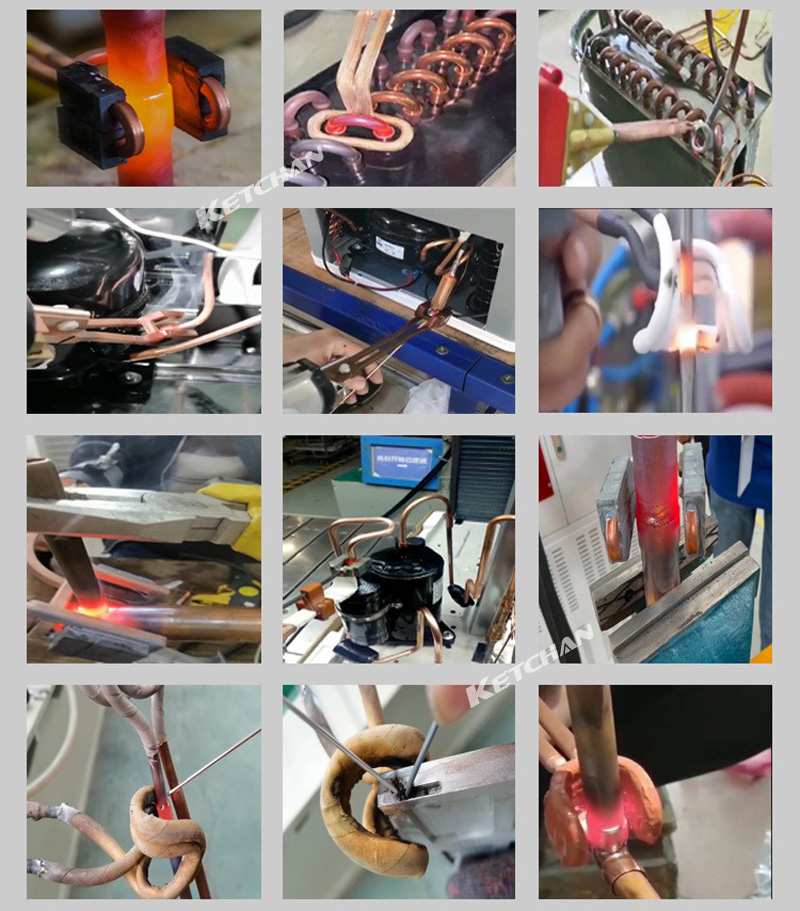

- Portable induction brazing machine is used in refrigeration and HVAC industry, automobile industry, household appliance industry, medical equipment industry, etc.

- Adaptation process: induction brazing of air conditioning and refrigeration valve parts, refrigerator freezer pipeline parts, solar energy parts, compressor parts, washing machines (tube-to-tube connection, tube-to-shell connection, tube-to-valve connection), evaporators and compressors in auto parts Brazing processes such as the connection of the motor, the short-circuit ring of the motor, etc.

- Handheld portable Induction brazing for complex and inaccessible workpieces or workshop locations, small size, space-saving, easy to move, and easy to operate.

- Induction brazing systems can be used for almost any brazing task. Until now, our systems were commonly used in the electrical technology industry for brazing generator and transformer components such as rods, strands, rings, wires, and sc rings. They also braze fuel lines, alternating current, and brake components for the automotive industry. Aviation uses induction brazing of fan blades, casing blades, fuel, and hydraulic systems. In the household goods industry, our systems braze compressor components, heating elements, and faucets.

Portable Induction Brazing Machine Applications

Tags:applications of induction brazing, copper brazing equipment, copper pipe brazing machine, features of induction brazing, handheld induction brazing applications, induction braze welding, induction brazing, induction brazing advantages, induction brazing benefits, induction brazing hvac, induction brazing machine manufacturer, induction brazing machine prices, induction heating applications, induction heating equipment, induction soldering, induction welding, portable brazing machine, portable induction brazing applications, portable induction brazing machine for copper pipe, portable induction heating machine, portable induction welder, portable silver brazing, portable welding machine

Relate Products

-

Induction Brazing System

Portable Induction Soldering Machine

-

Portable Induction Heaters

Portable Induction Brazing Heater

-

Portable Induction Heaters

Portable Handheld Induction Heater

-

Portable Induction Heaters

Portable Induction Welding Machine

-

Portable Induction Heaters

Portable Induction Brazing Machine

-

Portable Induction Heaters

Portable Induction Heating Machine