KETCHAN Induction provides integrated induction forging machines for forging diathermy of copper, aluminum, or steel billets. KETCHAN’s medium frequency induction machine power range is 20KW-3000KW.

According to the requirements, it can be equipped with automatic feeding, automatic temperature measurement, automatic sorting, automatic heating, automatic conveying and manipulator, etc.

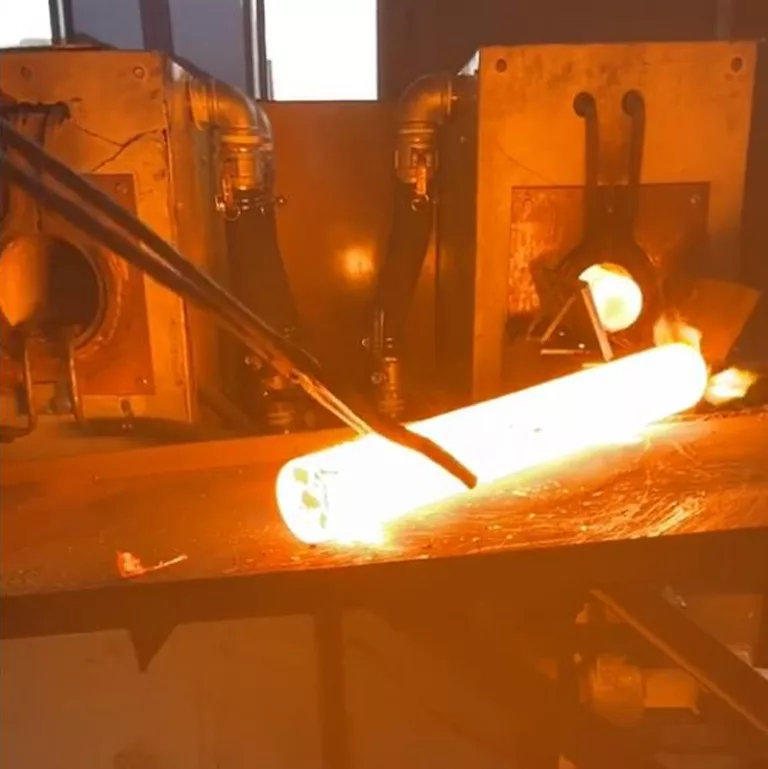

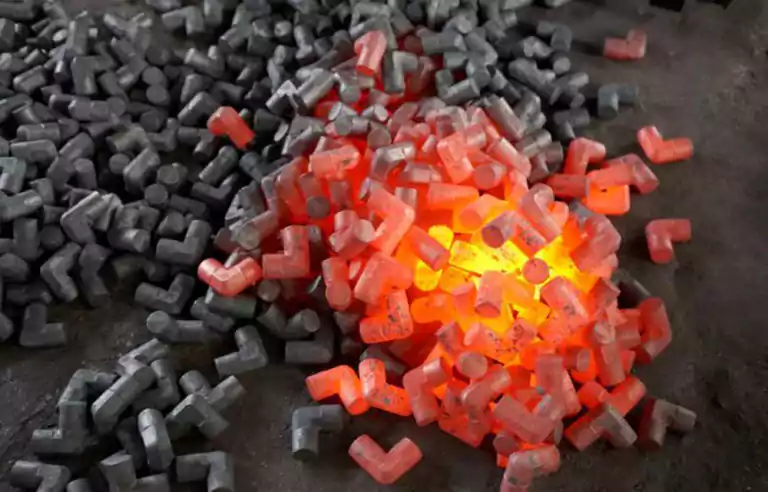

KETCHAN‘s induction forging machines adopt the principle of electromagnetic induction heating, and the heating speed is fast, so that the oxidation time of the metal bar during heating is short, and the oxide scale produced is greatly reduced, which improves the utilization rate of the metal blank, reduces the burning loss of the metal, and reduces the production. cost. Due to the reduced heating loss and basically no scale, the user can reduce a dephosphorization process to reduce costs.

Because there is no open flame and no harmful gas, the production environment is greatly improved, so many customers choose our equipment to replace the previous heating process with coal gas or natural gas.

Induction forging Machines for Sale

Medium Frequency Induction Heating Equipment

1 Medium frequency induction heating equipment manufacturer

2 Full solid IGBT induction heating equipment

3 Easy to install and no high voltage

4 Wide

Induction Forging Machine

1 PLC controlled induction forging machine

2 Intelligent DSP digital control technology

3 Automatic induction forging system

4 Energy saving and environmental protection <br

Automatic Forging Equipment

1 Digital automatic forging equipment with PLC controller

2 Good induction heating forging depth fast speed

3 Stable functions can 24 hours non stop working <br

Induction Rod Forging Furnace

1 Automated induction rod forging furnace

2 Medium frequency uniform heating result

3 Simple operation easy to installation

4 With automatic temperature controller <br

Billet Induction Forging Furnace

1 Large billet induction forging machine

2 Fast heating speed uniform forging result

3 Wide frequency range

4 Customized induction forging coils

Billet Induction Forging Furnace

1. Large billet induction forging machine.

2. Fast heating speed, uniform forging result.

3. Wide frequency range.

4. Customized induction forging coils.

5. 24 hours contineously working.

Induction Rod Forging Furnace

1. Automated induction rod forging furnace.

2. Medium frequency, uniform heating result.

3. Simple operation, easy to installation.

4. With automatic temperature controller.

5. Low power consumptions,perfect after sales.

Automatic Forging Equipment

1. Digital automatic forging equipment with PLC controller.

2. Good induction heating forging depth, fast speed.

3. Stable functions, can 24 hours non-stop working.

4. Fast heating speed, uniform forging results.

5. Perfect after-sales service.

6. Have passed CE, SGS, ISO9001 certifications.

Induction Forging Machine

1. PLC controlled induction forging machine.

2. Intelligent DSP digital control technology.

3. Automatic induction forging system.

4. Energy saving and environmental protection.

5. One key operation, multiple languages switch.

6. Provide overseas installation training guidance.

Medium Frequency Induction Heating Equipment

1. Medium frequency induction heating equipment manufacturer.

2. Full solid IGBT induction heating equipment.

3. Easy to install and no high voltage.

4. Wide application range, 24 hours non-stop working.

5. PLC digital control, more intelligent.

Free technical advice. The experienced engineering team is ready for you!

Machine Features

- Electromagnetic induction to heat metals without direct contact reduces oxidation and improves metallurgical quality.

- Heat metals rapidly and uniformly, which increases productivity and efficiency.

- Can heat all or only a portion of the metal, which allows for precise control and flexibility.

- Safe and reliable, as our machines have instant on and off heating that prevents overheating or melting of the metal surface.

- Cost-effective, as our machines reduce energy consumption compared to other heating methods like gas furnaces or resistance heating.

- Our machines are easy to integrate into production lines, as they have various options for automated or manual loading and unloading.

Optional Equipment

- Automatic feeding device: step type, flat push type, turntable type or clamping mechanical arm can be selected according to the shape of the workpiece.

- Infrared Thermometer: This device measures the temperature of metal parts without touching them, which helps to ensure optimum heating levels and avoid under- or overheating.

- Discharge automatic sorting device: select whether the workpiece is qualified according to the temperature measurement result

- Customized induction coil: Round, square or open type can be selected according to the shape of the workpiece and the heating position.

- Industrial chiller or water cooling tower: It can reduce the temperature of the water used to cool the induction coil, which can save energy and water consumption, and can extend the life of the induction heating power supply and induction coil.

Applications

Induction forging machines can be used to preheat aluminum rods, copper rods, billets, or ingots to a malleable state before being forged into the desired shape with a hammer or press. This equipment enables fast and uniform heating, precise temperature control, and high energy efficiency. They also reduce scale formation, oxidation, and decarburization of metal surfaces.

Induction Heating Forging Machine

What is an induction heating forging machine? An induction heating forging machine is a device that uses induction heating to preheat metals and shape them into desired forms using a

Brass and Copper Induction Forging Furnace

https://www.youtube.com/watch?v=LTwJzcFRMCE The extrusion temperature is usually between 400-600 ℃, and the extrusion temperature varies with different materials. The traditional heating method is resistance furnace heating, and the spindle is

Fasteners Machining with Induction Heating

Fasteners machining with induction heating is a process that involves using an electric current to heat and shape metal parts such as bolts, screws, nuts, and washers. Induction heating

Industries

• Automotive: Induction forging machines are used to produce parts such as axles, gears, shafts, bearings and valves. They can also be used to repair damaged parts by heating and reshaping.

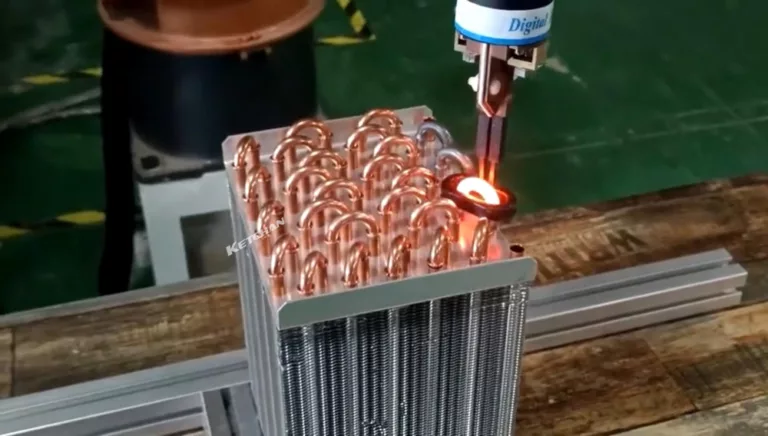

• Aerospace: Induction forging machines are used to forge components such as turbine blades, engine casings, landing gear and fasteners. They can also be used to braze complex metal assemblies such as heat exchangers and fuel injectors.

• Mining: Induction forging machines are used to forge tools such as drills, picks, hammers, and chisels. They can also be used to heat and harden the tips of tools for increased durability and performance.

• Structural: Induction forging machines can be used to forge structural elements such as beams, rods, rods, and tubes. They can also be used to bend and flatten metal tubes for various applications.

• Agriculture: Induction forging machines are used to forge tools such as plows, rakes, hoes, and shovels. They can also be used to heat and weld metal parts such as blades, chains, and hooks.

Induction Heating Solutions for Auto Parts

Advantages and Disadvantages of Induction Heat Treatment Auto Parts Induction heat treatment is a process that uses electromagnetic fields to heat metal parts or components without direct contact. It is

Induction Heating of Composite Materials

Induction heating is a technology that uses an alternating electromagnetic field to heat ferromagnetic and conductive materials and has been adapted to polymeric materials and composites in the past

What can Induction Heating Technology Do for the 5G Industry?

Induction heating technology can potentially provide benefits for the 5G industry in terms of manufacturing, testing, and repairing 5G components and devices. Such as: Manufacturing of 5G components and

Electric Vehicle Induction Heating & Hardening & Brazing

Electric Vehicles and Induction Heating In the past few years, people’s demand for electric vehicles has increased significantly, and electric vehicles have become a new track pursued by major

Induction Soldering Precision Solutions

What is induction soldering? Induction soldering works by using a precise electromagnetic field to heat two or more electrically conductive materials in order to join them with a filler

Induction Brazing Solutions For HVAC Industry

Composition of air conditioning accessories Air conditioning accessories include circuit control boards, wire controllers, manifolds, refrigerants, electronic expansion valves, motors, compressors, liquid mirrors, and ball valves. High-frequency induction brazing technology

FAQ

Why choose forging with induction heating?

- Process controllability: Unlike a traditional gas furnace, the induction system requires no pre-heat cycle or controlled shutdown and can be switched on and off as needed. The temperature and heating pattern can be precisely controlled and adjusted to suit different materials and shapes.

- Energy efficiency: Due to the heat being generated within the component, energy transfer is extremely efficient. The induction system consumes less power and produces less waste heat than other heating methods. It also reduces the emission of greenhouse gases and pollutants.

- Rapid temperature rise: High power densities and direct heating allow for fast and uniform heating of the metal parts, which increases productivity and efficiency. The heating time can be reduced from hours to minutes or even seconds.

- Improved quality: Induction forging reduces scale formation, oxidation, and decarburization of the metal surface, which improves the metallurgical quality and integrity of the forged parts. It also reduces distortion, cracking, and residual stresses, which enhances the mechanical properties and performance of the parts.

- Flexibility: Induction forging can heat all or only a portion of the metal part, which allows for precise control and flexibility in shaping and forming. It can also handle different sizes and shapes of metal parts, from small to large, simple to complex.

- Safety: Induction forging is a clean, non-contact method of heating that eliminates the risk of overheating or melting the surface of the metal part. It also reduces the noise, dust, smoke, and fire hazards associated with other heating methods.

These are some of the advantages of induction forging that make it a superior choice for various industries and applications.

Why choose KETCHAN's induction forging machines?

KETCHAN Induction is a leading manufacturer of induction forging machines with more than 20 years of production experience and expertise. We offer different types of induction forging machines for different applications and needs. Each equipment will be strictly tested before leaving the factory. We also provide customized solutions and after-sales service.