The Leading Induction Heating Machine Manufacturer

23+ years experience in R&D and production of induction heating machines. We are committed to energy conservation and sustainable development.

Customers in more than 40 countries use our induction heat treatment solutions to heat their workpieces. They use our industrial induction heating machine for heating, brazing, melting, forging, hardening, annealing, tempering, preheating, bending, quenching, stress-relieving, Shrink Fitting, and other processes.

Zhengzhou Ketchan Electronic Co., Ltd., founded in Zhengzhou, committed to providing the most suitable and economical induction heat treatment equipment eco chain for our global users for the last 23 years.

Until now, we have helped thousands of global heat treatment industries find smart induction heat treatment solutions in induction brazing, induction hardening, heat treating, shrink-fitting, annealing, induction melting, and other induction applications. In addition, Zhengzhou Ketchan offers user operator training, heating process development services, On-site face-to-face technical support, preventative maintenance and installation, and start-up assistance service for each of our users.

Turn-key Heating Projects

Happy Customers

Awards Received

Years In Service

Featured Induction Heating Machine Products

We focus on providing our users with the whole turnkey induction heating project. All products are strictly tested before leaving the factory.

Frequently Asked Questions

How Induction Heating Works?

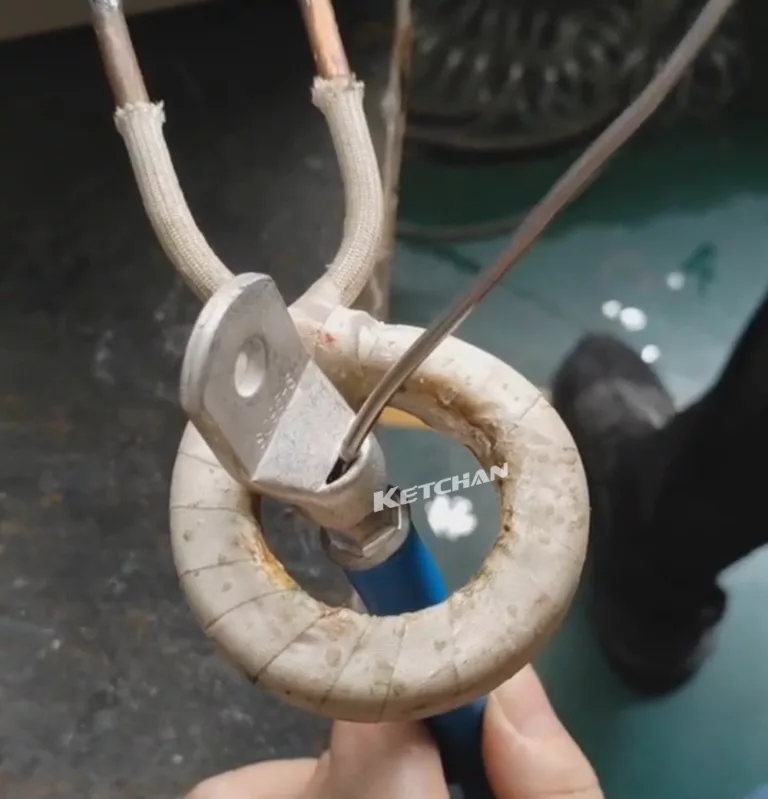

How exactly does induction heating work? Induction heating machine is mainly using the magnetic field principle to heat the workpiece, the induction heating system is mainly an induction coil, power supply and metal parts that need to be heated.

Induction heating power is converted from AC power to higher frequency AC power, which is transmitted to the induction coil to generate electromagnetic fields in the coil.

Because the metal workpiece that needs to be heated is also a conductor, the coils create loops of magnetic lines that pass directly through the metal workpiece placed in the coil, form a closed current loop,and metal has less resistance,also with a higher current.When these high-current magnetic induction heating lines pass through the metal workpiece, this makes the electrons inside the metal very active, bumping into each other and rubbing against each other to generate heat, which makes the metal itself very hot.

What Is Induction Heating Application?

Induction heating machine is widely used in industrial manufacturing, such as induction hardening, induction melting, induction welding, induction forging, and so on.

- Induction welding: Cutting, drilling tools, cutting tools, woodworking tools, lathe tool, drill bit, brazing, reamer, milling cutter, drill bit, saw blade serrate, glasses frame, steel pipe, copper pipe welding, cutting teeth, the same of dissimilar metal welding, compressor, pressure gauge, stainless steel pot, relay contact composite materials with different welding, welding transformer winding copper wire, storage (gas filling and the mouth of the welding, Welding of stainless steel table and kitchenware).

- Induction heat treatment: Gear, machine tool guide rail, hardware tools, pneumatic tools, power tools, hydraulic parts, ductile iron, auto parts, internal parts, and other mechanical metal parts (surface, inner hole, local, integral) induction quenching, induction annealing, stainless steel pot products stretching.

- Induction forging: Standard parts, fasteners, masterpieces, small hardware, straight shank twist drill, overall, local heating and twist drill hot rolling of hot upsetting. For round steel bar with diameter below 100mm, induction heating annealing of metal material for drawing, molding, embossing, bending, smashing head, steel wire (iron wire) heating nail, stainless steel products annealing, drawing, expansion, thermal expansion, etc.

- Induction melting: Our company has an induction melting furnace, and a vacuum induction melting furnace, and is widely used in all kinds of metal products, steel, stainless steel, brass, copper, aluminum, aluminum alloy, gold, silver and other metal materials smelting, smelting capacity from 3kg-10000kg. There are three types of melting furnaces: dump type, top out the type, and fixed type induction melting furnace.

- Other induction heating fields: aluminum plastic tube, steel plastic tube, cable, wire induction heating coating, metal induction preheating coating, semiconductor single crystal growth, heat matching, bottle mouth induction heating sealing, toothpaste skin heat sealing, powder coating, metal implanted plastic, food, beverage, pharmaceutical industry used aluminum foil sealing.

Induction heating is arguably one of the cleanest, most efficient, cost-effective, accurate, and repeatable materials heating methods available in the industry today. Especially with the advent of advanced engineering materials, alternative energy, and other needs, the unique function of induction heating technology for future industrial production provides a fast, efficient, and accurate heating method.

What We Offer?

We are in the induction heating treatment field for more than 20 years, and our induction heating machine is mainly used in the modern heat treatment factories for different metal heating applications. But in general, our product range is as follows:

- UHF induction heating machine

- Digital induction heating machine

- Induction heat treatment machine

- Automatic induction brazing system

- Portable induction heating machine

- Air-cooled induction heating machine

- CNC induction hardening machine tool

- Metal melting furnace

- Induction forging system

- Industrial cooling machine

- Resistance furnace

- Infrared thermometer

- Induction heating coil

- Custom induction heating systems

How To Find Right Induction Heating Solutions?

What is the efficiency of induction heating? Which frequencies are best for your application? The following guide will give you some introduction to the efficiency of induction heating. For more information, please contact ZHENGZHOU KETCHAN technical staff.

Induction heating machine, induction heating power supply selection generally need the following parameters:

- The shape of the workpiece being heated, the outer dimensions, and the weight of the workpiece is heated.

- The material composition of the workpiece to be heated (general induction heating, only for metallic conductors and non-metallic conductors such as graphite).

- The time required for the heating of the workpiece to be heated, and the target temperature.

- The heating efficiency requests.

Once the above data are confirmed, we can choose the related induction heating machine power and related induction heat treatment systems.

Why Use Induction Heating Machine?

We are considering that what we provide you can give you all the benefits in your productions. For this, we are developing unique induction heating treatment solutions for you together.

Because of the multi advantages of the induction heating technology. Now more and more factories are choosing induction heating as the main heat treatment source.

- Induction heating does not need to heat the workpiece as a whole, but can selectively heat the partial workpiece, so as to achieve less power consumption purpose, and the workpiece deformation is not obvious.

- Fast induction heating speed, which can make the workpiece reach the required temperature in a very short time, even within 1 second. So that the workpiece surface oxidation and decarbonization are relatively slight, most of the workpieces do not need gas protection.

- The surface hardened layer can be regulated by adjusting the operating frequency and power of the induction heating equipment as required. Therefore, the martensite structure of the hardened layer is fine, and hardness, strength, and toughness are relatively high.

- The workpiece after the induction heating treatment, there is a thick ductile area under the hard surface layer, with better compression internal stress, making the workpiece fatigue resistance and braking ability higher.

- Induction heating equipment is easy to install on the production line, easy to realize mechanization and automation, easy to manage, can effectively reduce transportation, save manpower, and improve production efficiency.

- One induction heating system can realize multi-purpose. Not only can complete induction quenching, induction annealing, induction tempering, induction normalizing, induction tempering, and other induction heat treatment processes but also can complete induction welding, induction melting, induction thermal assembly, induction thermal disassembly induction diathermy forming, and other work.

- Easy to use, easy to operate, and can be started or stopped at any time. And without preheating.

- Not only can do the manual operation, semi-automatic but also automatic operation; It can work continuously for a long time, or stop used randomly. It is conducive to the use of equipment in the preferential period of power supply through price.

- High power utilization rate, environmental protection, and energy saving, safe and reliability, good working conditions for workers, national advocates, and so on.

How To Get A Quick Quote?

We are considering that what we provide you can give you all the benefits in your productions. For this, we are developing unique induction heating machine solutions for you together.

You can please send us some requests with some key information on your induction heating process. This can help us to make clear your framework conditions. Once we are clear about your requests, you will get a detailed offer on the induction heating system as soon as possible. This offer will include the induction heating process description and quotation sheet, also we will test your workpiece in our heat treatment lab as well. After that, you will check the finished parts details and place the order from us. We manufacture your induction heating machine solution, deliver it and take care of the technical interfaces.

Induction soldering is a process that has a wide range of applications across various industries due to its ability to provide rapid, consistent, and precise heating. Here are some of the key applications: Automotive Industry It’s used for soldering components

What’s It? Post-weld heat treatment (PWHT) of steel structures is a process that involves reheating the welded joints to a certain temperature and holding them for a specified time. The purpose of PWHT is to improve the mechanical properties and

Thermal oil electromagnetic heating furnace, also known as organic heat carrier furnace, integrates safety, efficiency, and advanced technology to meet the needs of modern industrial processes. Represents a cutting-edge industrial solution. Thermal oil electric heating furnace Principle: Heat is generated

KETCHAN‘s engineers have sorted out and summarized some practical problems in the project after long-term contact with customers. The general issues that customers are concerned about include the following. Induction brazing test finished products display Q: The induction coil looks