Outstanding advantages:

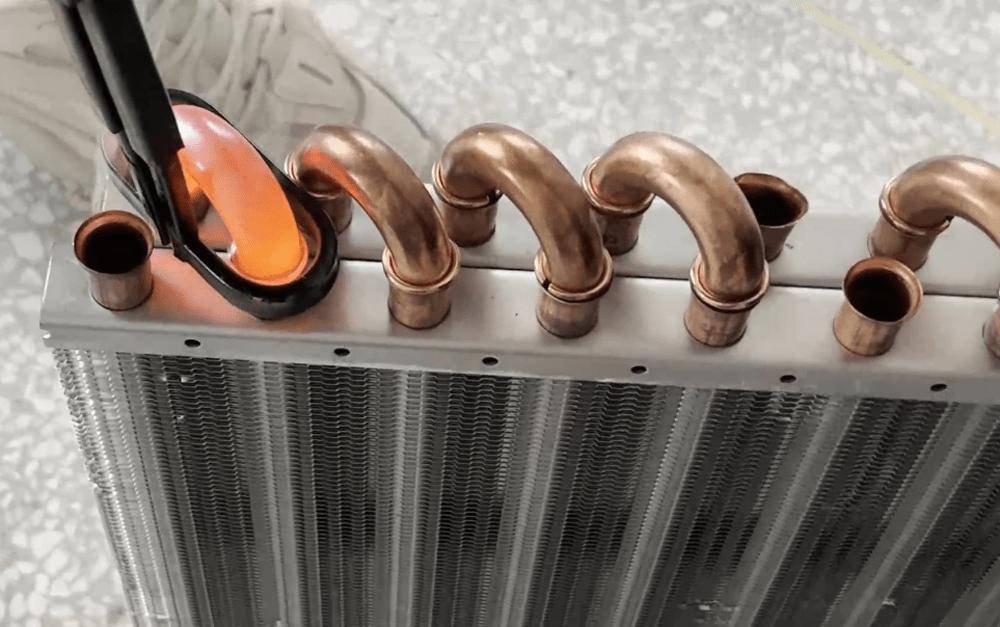

- Using soldering rings, there is almost no solder waste.

- Using induction brazing of copper pipes or copper components, 100% penetration can be easily achieved. The yield rate can be greatly improved.

- Heating time and temperature are controlled by the machine, which can significantly save labor costs and provide better product consistency.

- The induction coil is replaceable and compatible with more products.

Why braze copper pipes with induction heating?

Induction brazing is a type of brazing that uses induction heating to heat the metal parts and the filler metal. Induction brazing is a subset of induction heating, which is a process that uses an electromagnetic field to heat a metal object without direct contact.

Using induction heating for brazing copper pipes, which is a method of joining metal parts with a filler metal that melts at a lower temperature than the base metals. Some of the advantages of using induction heating for copper pipe brazing are:

- Induction heating is faster and more energy-efficient than other methods, such as flame brazing or furnace brazing. Induction heating can heat the copper pipes and the filler metal in seconds, while other methods may take minutes or hours.

- Induction heating is more precise and consistent than other methods, as it can control the temperature and the heat zone of the brazing process. Induction heating can avoid overheating or underheating the copper pipes and the filler metal, which can affect the quality and strength of the joint.

- Induction heating is safer and cleaner than other methods, as it does not produce any flames, smoke, or fumes. Induction heating can also reduce the risk of fire hazards, burns, or injuries to the operator or the environment.