Induction welding is widely used in life, automobiles, air conditioners, aviation, nuclear industry, shipbuilding, construction, etc., especially in industry, are used the most, and with the development of China’s economy, welding technology has become an indispensable processing means.

This picture must be familiar to everyone. I remember that when I was a child, I often saw it when I passed by a car repair shop. Now I see it and it is very emotional. The sparks are flying.

But now, with the continuous advancement of science and technology, this kind of manual welding can also be seen, because small workshops use a little more, but in order to improve work efficiency and save costs, cremation-free welding has appeared, and this induction heating The most important point of the method is that it has low cost and high efficiency, and is generally used in medium-sized and large-scale industries.

So what are the advantages of induction heating?

- Fast heating speed, not easy to deformation;

- Slight oxidation;

- High efficiency.

- Automation

- Low cost.

- Security and environmental protection.

- Workers have low technical requirements.

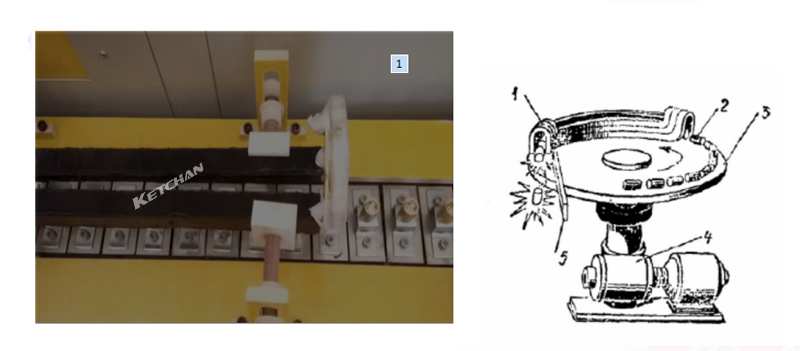

Linear induction brazing system

Induction brazing welding technical process:

Clamp -> Place solder -> Welding -> Cleaning

1. Workpiece clamping

Don’t look at it as a simple fixture, but in order to ensure the welding effect, induction heating has four requirements for the fixture:

1). High positioning accuracy;

2). Simple operation.

3). Good heat conduction or insulation;

4). High degree of automation, reduces manual intervention.

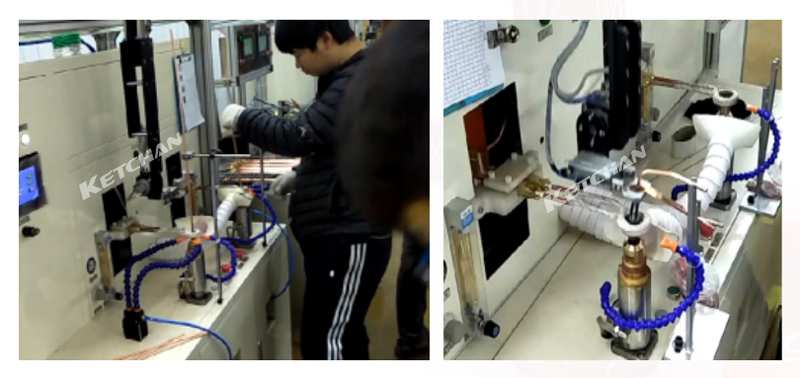

Double stations induction brazing system

2. Place the brazing flux

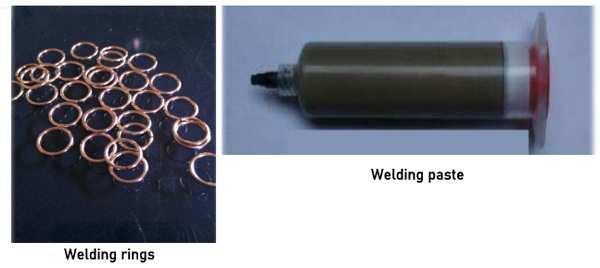

Once the product is clamped, the solder can be placed. There are two main forms of commonly used solder, the first is to use solder ring, the second is to use solder paste.

Solders for induction brazing

3. Induction Brazing

Once the solder is in place, it’s time to solder. The welding process of induction brazing is fully automatic and only needs to be pressed by the operator to start welding automatically.

4. Clean

During the soldering process, there will be some slight oxide scale or residues of additives. After induction welding, it can be cleaned by ultrasonic cleaning or chemical cleaning.

Application fields of induction brazing:

1. Induction brazing of solenoid valve and HVAC pipes:

2. Automobile air conditioning pipeline assembly:

3. New energy vehicle battery pack water cooling belt and water cooling plate:

Tags:AC copper tube brazing machine, aluminum induction welding machine, automobile induction welding machine, automotive AC brazing machine, automotive HVAC induction brazing machine, copper tube induction brazing machine, for Sale, HVAC brazing machine, induction braze welding machine, induction brazing machine, induction heater, induction heating, induction heating machine, induction machine, induction soldering machine, induction welding machine, KETCHAN, KETCHAN Electronic, manufacturer, Manufacturers, price, supplier, Suppliers, Zhengzhou KETCHAN, Zhengzhou KETCHAN Electronic