KETCHAN induction specializes in industrial induction heaters, which are devices that use electromagnetic fields to heat metal parts or components without direct contact. Industrial induction heaters have various applications, such as brazing, melting, forging, hardening, annealing, tempering, preheating, bending, quenching, stress-relieving, shrink fitting, and more.

An industrial induction heater is a type of induction heating machine that can heat metal objects quickly and efficiently. There are different kinds of induction heaters, such as UHF induction heaters, air-cooled induction heaters, portable induction heaters, and ultra-high frequency induction heaters. Each kind of induction heater has its own advantages and disadvantages, depending on the size, shape, material, and heating requirement of the metal object.

Fortunately, KETCHAN induction entered the field of induction heating in 2000 and has produced industrial induction heaters for more than 20 years. Our engineers have rich application experience and can help you choose the industrial heater that suits you faster.

Industrial Induction Heaters for Sale

High Frequency Induction Heater

1 IGBT high frequency induction heater manufacturer

2 Match well with the induction heating coils

3 Fast heating speed well controlled temperature

4 Stable

Medium frequency Induction Heater

1 IGBT medium frequency induction heater

2 Machine frequency level is from 0 1 20KHZ

3 Stable heating no oxidation no deformation

4 Match

Ultra high frequency induction heater

1 250KHZ ultra high frequency induction heater

2 Small volume fast heating treatment speed

3 High frequency level wide application ranges

4 IGBT series

Induction Billet Heater

1 Induction billet heater frequency range 0 1 20Khz

2 For whole bar forging and partial bar forging cases

3 The finished forging parts are uniform

Mini Induction Heater

1 No high voltage safe operation

2 Mini induction heater adopts siemens IGBT

3 Perfect protection functions

4 Match temperature controller

5

Handheld Induction Heater

1 All handheld induction heater with Siemens IGBT

2 All induction heaters with one stop service

3 Mainly used for copper tube induction brazing

Mobile Induction Heater

1 Mobile induction heater is for HVAC copper tube brazing

2 Small volume fast brazing speed

3 Adopt parallel resonance circuit mode

4 With

Flexible Induction Heater

1 Flexible induction heater with PLC controller

2 With temperature controller

3 Intelligent DSP automatic tracking technology

4 Small volume light weight easy movement

Industrial Induction Heater

What is an industrial induction heater? An industrial induction heater is a device that uses magnetic induction to heat electrically conductive materials such as metals1. They are used for various

High Frequency Induction Heater

1. IGBT high frequency induction heater manufacturer.

2. Match well with the induction heating coils.

3. Fast heating speed,well controlled temperature.

4. Stable functions, 24 hours continuously working.

5. Wide application ranges, perfect alarm functions.

6. With CE, SGS, ISO9001 certifications.

Medium frequency Induction Heater

1. IGBT medium frequency induction heater.

2. Machine frequency level is from 0.1-20KHZ.

3. Stable heating, no oxidation, no deformation.

4. Match industrial chiller, 24 hours working.

5. We are end manufacturer,fast delivery time.

6. With CE,SGS, ISO9001 certification.

Ultra high frequency induction heater

1. 250KHZ ultra high frequency induction heater.

2. Small volume, fast heating treatment speed.

3. High frequency level, wide application ranges.

4. IGBT series circuit, no high voltage.

5. Match industrial chiller, 24 hours working.

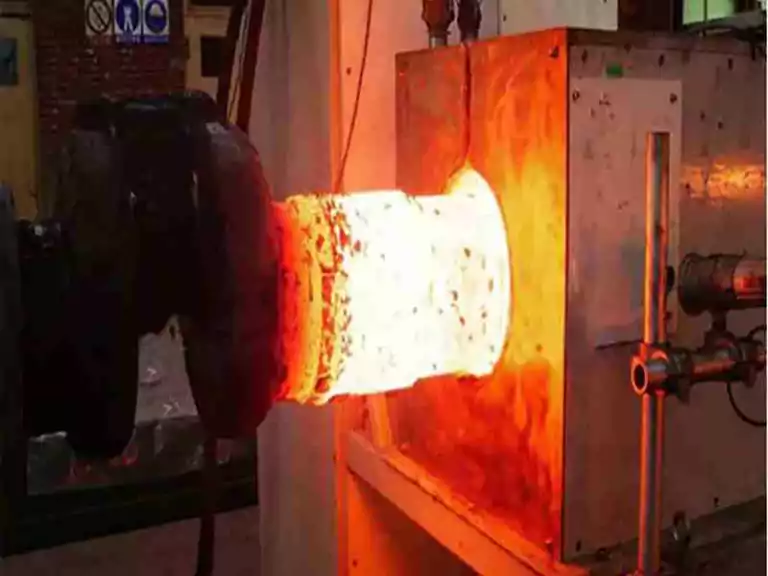

Induction Billet Heater

1. Induction billet heater frequency range 0.1-20Khz.

2. For whole bar forging and partial bar forging cases.

3. The finished forging parts are uniform.

4. Fast heating speed, energy-saving.

5. More than 20 years manufacturer experience.

Mini Induction Heater

1. No high voltage, safe operation.

2. Mini induction heater adopts siemens IGBT.

3. Perfect protection functions.

4. Match temperature controller.

5. 24 hours non-stop working.

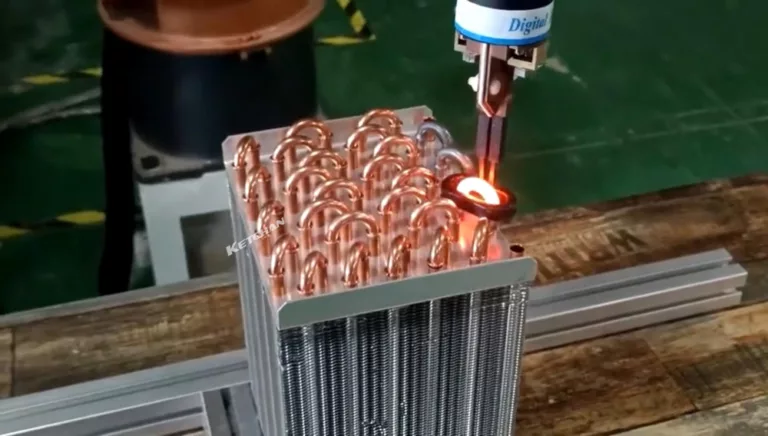

Handheld Induction Heater

1. All handheld induction heater with Siemens IGBT.

2. All induction heaters with one-stop service.

3. Mainly used for copper tube induction brazing.

4. Handheld induction heater with stable quality.

5. Easy to operate and install.

6. With perfect after-sales service.

Mobile Induction Heater

1. Mobile induction heater is for HVAC copper tube brazing.

2. Small volume, fast brazing speed.

3. Adopt parallel resonance circuit mode.

4. With flexible cables 5-20m.

5. With industrial chiller, long using life.

Flexible Induction Heater

1. Flexible induction heater with PLC controller.

2. With temperature controller.

3. Intelligent DSP automatic tracking technology.

4. Small volume, light weight, easy movement.

5. Have CE, SGS certification.

6. We are a manufacturer.

Industrial Induction Heater

What is an industrial induction heater? An industrial induction heater is a device that uses magnetic induction to heat electrically conductive materials such as metals1. They are used for various

Free technical advice. The experienced engineering team is ready for you!

Features

Some of the features of industrial induction heaters are:

• They can heat metal objects of different shapes, sizes and materials such as steel, copper, brass, aluminum and more.

• They allow precise and uniform heating with high efficiency and low energy consumption.

• They can control temperature, power and heating time by microprocessor or temperature probe.

• They can operate at different frequencies, ranging from low frequency (500 Hz) to very high frequency (2MHz), depending on heating requirements and penetration depth.

• They can be portable, air-cooled or water-cooled, depending on the size and cooling capacity of the unit.

• They can have various types of coils such as solenoid, pancake, spiral or custom made to fit the shape of the metal object.

Optional Equipment

• Custom induction coils: The induction coil is customized according to the customer’s application requirements.

• Footswitch: Use the foot switch to control the operation of the induction heater.

• Infrared thermometer: Realize temperature monitoring and control of the induction heater.

• Industrial water chillers: for cooling induction coils and quenching workpieces

Applications

- Bearing mounting and dismounting: Induction heaters can be used to heat bearings and other components for easy installation or removal.

- Brazing and soldering: Induction heaters can be used to join metal parts by melting a filler metal between them. KETCHAN induction provides handheld and automated brazing systems that use induction heating for various industries.

- Heat treating: Induction heaters can be used to harden, temper, anneal, or normalize metals by controlling the temperature and time of heating. We offers inductive heating systems for various heat treating processes.

- Plastic processing: Induction heaters can be used to heat plastic materials or molds for injection molding, extrusion, thermoforming, or welding. We also provide inductive heating systems for plastic processing applications.

- Drying and curing: Induction heaters can be used to dry or cure paints, coatings, adhesives, or other materials on metal surfaces.

Induction Brazing (with pictures, videos, applications)

What’s Induction Brazing? Get A Quote https://www.youtube.com/watch?v=io3fURkB0WE Induction brazing is using alternating magnetic field – electromagnetic induction phenomenon, the eddy current effect in the magnetic field heats the workpiece,

Induction Melting (with pictures, videos, applications)

What’s Induction melting? Get A Quote https://www.youtube.com/watch?v=kyGyJAh667s The induction melting furnace is based on the electromagnetic induction heating principle to work, through electromagnetic induction to generate heat, the heating

Induction Forging (with pictures, videos, applications)

What’s Induction forging? Get A Quote https://www.youtube.com/watch?v=78B3X_PQrX0 The core principle of induction forging furnace is to convert power frequency 50HZ AC to medium frequency (300HZ-20khz). The three-phase alternating current

Induction Hardening (with pictures, videos, applications)

What’s Induction Hardening? Get A Quote https://www.youtube.com/watch?v=4R0me_Blhic Induction hardening is a quenching method that uses the principle of electromagnetic induction to make the workpiece cut magnetic field lines in

Induction Annealing (with pictures, videos, applications)

What’s Induction annealing? Get A Quote Induction annealing is a part of induction heating. The purpose of induction annealing is to change the metal material’s hardness, toughness, and internal stress

Induction Tempering (with pictures, videos, applications)

What’s Induction tempering? Get A Quote For the whole induction hardening workpiece, especially the induction through heating hardening workpiece, the application of induction heating tempering is more convenient to form

Industries

Industrial induction heaters are suitable for various industries that require heating, melting, joining, or processing of metals or other electrically conductive materials. Some of the industries that use industrial induction heaters are:

- Metallurgy: Induction heating is used for heat treatment, such as hardening, tempering, annealing, or normalizing of metals. It is also used for melting and forging of metals, such as steel, copper, brass, gold, silver, aluminum, or carbide.

- Semiconductor: Induction heating is used for Czochralski crystal growth and zone refining of silicon and other semiconductors. It is also used for heating graphite crucibles that contain the molten materials.

- Plastic processing: Induction heating is used for heating plastic materials or molds for injection molding, extrusion, thermoforming, or welding. It is also used for drying and curing of paints, coatings, adhesives, or other materials on plastic surfaces.

- Textile: Induction heating is used for heating rollers, rolls, or cylinders that are involved in textile manufacturing processes. It is also used for drying and curing of fabrics or fibers.

- Paper: Induction heating is used for heating rollers, rolls, or cylinders that are involved in paper manufacturing processes. It is also used for drying and curing of paper or pulp.

- Brazing and soldering: Induction heating is used for joining metal parts by melting a filler metal between them. It is also used for soldering of electronic components or circuits

These are some of the industries that use industrial induction heaters. However, there may be more industries that can benefit from this technology. If you want to learn more about industrial induction heaters and their applications, you can check out induction heating knowledge.

Induction Heating Solutions for Auto Parts

Advantages and Disadvantages of Induction Heat Treatment Auto Parts Induction heat treatment is a process that uses electromagnetic fields to heat metal parts or components without direct contact. It is

Induction Heating of Composite Materials

Induction heating is a technology that uses an alternating electromagnetic field to heat ferromagnetic and conductive materials and has been adapted to polymeric materials and composites in the past

What can Induction Heating Technology Do for the 5G Industry?

Induction heating technology can potentially provide benefits for the 5G industry in terms of manufacturing, testing, and repairing 5G components and devices. Such as: Manufacturing of 5G components and

Electric Vehicle Induction Heating & Hardening & Brazing

Electric Vehicles and Induction Heating In the past few years, people’s demand for electric vehicles has increased significantly, and electric vehicles have become a new track pursued by major

Induction Soldering Precision Solutions

What is induction soldering? Induction soldering works by using a precise electromagnetic field to heat two or more electrically conductive materials in order to join them with a filler

Induction Brazing Solutions For HVAC Industry

Composition of air conditioning accessories Air conditioning accessories include circuit control boards, wire controllers, manifolds, refrigerants, electronic expansion valves, motors, compressors, liquid mirrors, and ball valves. High-frequency induction brazing technology

FAQ

How to choose an industrial induction heater?

Some of the main factors are:

• The material of your part: Different metals have different resistivity, magnetic properties, and heating characteristics. You should choose an induction heater that can heat your part efficiently and effectively.

• The depth of heating penetration: The induced current will be more intense on the surface of your part than in the core. You should choose an induction heater that can heat your part to the desired depth and uniformity.

• The operating frequency: The frequency of the alternating current affects the heating penetration and speed. Lower-frequency, higher-power systems are suitable for through heating, while higher-frequency, lower-power systems are suitable for surface heating.

• The applied power: The output power of your induction heater determines how fast your part is heated. You should choose an induction heater that can provide enough power to heat your part in the required time and temperature.

• The rise in temperature required: The temperature change that you want to achieve in your part affects the power and time needed for heating. You should choose an induction heater that can meet your temperature specifications.

• The shape and size of your part: The geometry of your part affects the design and configuration of the induction coil. You should choose an induction heater that can accommodate your part and provide optimal coupling and heating.

• The type of heating process: Different heating processes have different requirements and objectives. You should choose an induction heater that can perform the heating process that you need, such as brazing, soldering, heat treating, plastic processing, drying, curing, etc.

• The special features and controls: Some induction heaters have additional features and controls that can enhance the performance and efficiency of the heating system.

How to maintain industrial induction heaters daily?

• Inspect the induction coil and bus work: Check the coil and bus work for any signs of wear, damage, corrosion, or loose connections. Clean the coil and buswork with a soft cloth or brush to remove any dust, dirt, or scale. Replace any damaged or worn parts as soon as possible.

• Inspect the heat treat fixtures and quenching apparatus: Check the fixtures and quenching apparatus for any signs of wear, damage, leakage, or clogging. Clean the fixtures and quenching apparatus with a soft cloth or brush to remove any debris or residue. Replace any damaged or worn parts as soon as possible.

• Inspect the melting furnaces and leads: Check the furnaces and leads for any signs of wear, damage, overheating, or arcing. Clean the furnaces and leads with a soft cloth or brush to remove any slag, oxide, or carbon. Replace any damaged or worn parts as soon as possible.

• Inspect the forging coils and water-cooled skid rails: Check the coils and skid rails for any signs of wear, damage, corrosion, or leakage. Clean the coils and skid rails with a soft cloth or brush to remove any scale, rust, or grease. Replace any damaged or worn parts as soon as possible.

• Inspect the air and hydraulic components: Check the air and hydraulic components for any signs of wear, damage, leakage, or contamination. Clean the air and hydraulic components with a soft cloth or brush to remove any dust, dirt, or oil. Replace any damaged or worn parts as soon as possible.

• Inspect the water-cooling system: Check the water-cooling system for any signs of wear, damage, leakage, clogging, or contamination. Clean the water-cooling system with a soft cloth or brush to remove any scale, algae, or sediment. Replace any damaged or worn parts as soon as possible.

• Inspect the power supply and heat station: Check the power supply and heat station for any signs of wear, damage, overheating, or malfunctioning. Clean the power supply and heat station with a soft cloth or brush to remove any dust, dirt, or moisture. Replace any damaged or worn parts as soon as possible.

• These are some of the basic steps that you can follow to maintain your industrial induction heaters daily. However, you should also consult your equipment manual for more specific instructions and recommendations for your particular system.